Product description

The fire-fighting cyclone preventer is a special pipe used to prevent the water tank (pool) from generating swirling flow when transporting liquid and prevent air from entering the pipeline. Its function is to install on the water tank (pool) water pump suction pipe port to eliminate the swirling flow in the water tank (pool) to ensure that the water pump can always start and work normally, avoid air entering the water pump and cause cavitation, which can make the water tank The liquid level of the conveyed liquid in the (pool) drops to a lower level to ensure that the maximum flow rate is reached.

Product advantages

1. The fire water tank cyclone preventer is designed and manufactured in accordance with the European standard EN12845. The minimum submergence depth can reach 100mm without swirling, which greatly improves the effective utilization rate of the pool.

2. Effectively eliminate the swirling flow generated by the water tank (pool) in the process of pumping water.

3. Prevent the air from entering the water pump due to the swirling flow, realize the high-efficiency water delivery of the water pump, and avoid the damage of the water pump due to cavitation.

4. The structure of the swirl preventer is simple and strong, realizing economical installation and maintenance-free.

5. The material of the swirl preventer can be high-quality austenitic stainless steel 06Cr19Ni10 (304), or HT200 cast iron and Q235 carbon steel, with strong corrosion resistance and long service life.

6. Meet the sanitary requirements of GB/T 17219.

7. The cyclone preventer of the fire water tank can be equipped with a filter.

Technical parameter

Connection flange pressure rating | 1.0MPa ,1.6MPa ,2.5MPa |

Working medium | Direct drinking water, drinking water, water, sewage, oil, weak acid or weak alkali medium |

Operating temperature | 0~120℃ |

Material | 06Cr19Ni10 (304), the material composition meets the GB/T 20878 standard |

Use requirements according to standards | GB 50974, which also complies with the standard design requirements of the European standard BS EN12845 |

Flange connection size according to standard | GB/T 17241.6, also in line with B.S.4504 |

Standards compliant | Hygienic requirements of GB/T 17219 |

Main specifications and dimensions

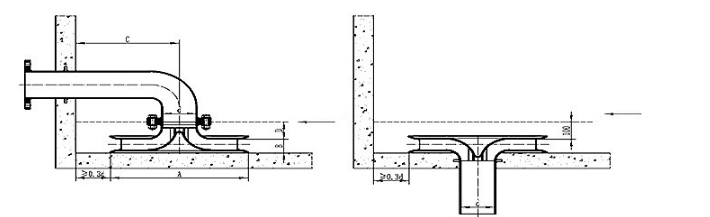

Prevent vertical installation of cyclone | |||||||||||

Nominal diameter of pipe(DN) | 65 | 80 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 |

Prevent wide band A on the top plate of cyclone | 220 | 220 | 423 | 623 | 827 | 1030 | 1232 | 1232 | 1232 | 1232 | 1232 |

Prevent the width of the top plate of the cyclone B | 44 | 44 | 54 | 79 | 101 | 130 | 155 | 191 | 191 | 209 | 209 |

Prevent cyclone position C | 300 | 310 | 412 | 512 | 614 | 715 | 816 | 816 | 816 | 816 | 816 |

Allow low water level D of the water tank (to prevent cyclone) | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

Jing12011202000600

Jing12011202000600