Diaphragm hydraulic/pneumatic quick opening mud valve

Product overview

Product model: JM744X, JM644X

Nominal diameter: DN100~400mm

Nominal pressure: PN0.6~1.0MPa

Minimum horse drive pressure: 0.15MPa

Applicable medium: water, sewage

Drive medium: clean water, gas

Applicable temperature: 0~80℃

Flange standard: GB/T17241.6 B/T 9113

Test standard: GB/T 13927 APl 598

Product description

Diaphragm hydraulic/pneumatic quick-opening sludge discharge valve, also known as cover valve, is often used to discharge sludge at the bottom of sedimentation tanks in urban water plants and sewage treatment plants. The applicable medium of the sludge valve is raw sewage. The temperature of the medium should generally be less than 50°C, and its working water depth should be less than 10 meters. The sludge valve is also used in the water treatment plant to discharge the sludge and waste water in the pool. The sludge discharge valve has an angular structure with a nylon reinforced rubber diaphragm inside, which can be used for long-term use of the sludge valve.

Diaphragm hydraulic/pneumatic quick-opening mud valve is a kind of angle cut-off valve with hydraulic source or pneumatic source as the actuator. Usually installed in rows on the outer side wall of the bottom of the sedimentation tank to remove the sediment and dirt at the bottom of the tank. The valve is divided into two chambers by a nylon reinforced rubber diaphragm, connected to a hydraulic or pneumatic source, and controlled by an electric or manual two-position four-way reversing valve to achieve rapid mud discharge. The valve replaces the piston with a diaphragm, and has no movement friction. It is more suitable for granular media such as mud and greatly improves the service life of the valve.

Material of main parts

Part Name | Body, bonnet | Diaphragm pressure plate, valve disc | Stem | Diaphragm |

Material | Cast iron, ductile iron, carbon steel | Ductile iron, bronze | Stainless steel | Nylon reinforced rubber |

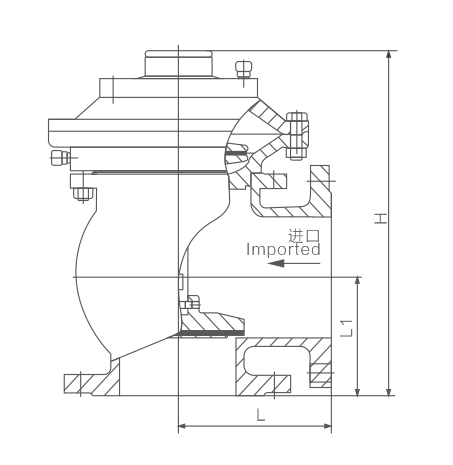

Main external connection size

DN | 100 | 150 | 200 | 250 | 300 | 350 | 400 |

L | 160 | 190 | 225 | 260 | 280 | 315 | 340 |

L1 | 120 | 150 | 190 | 220 | 260 | 300 | 340 |

H | 370 | 440 | 530 | 615 | 785 | 880 | 970 |

Jing12011202000600

Jing12011202000600