Rubber check valve

Product overview

General model: HC44X

Nominal diameter: DN50mm-DN600mm

Nominal pressure: PN1.0MPa-1.6MPa

Applicable media: water and oil.

Applicable temperature: 0℃-80℃

Material of body: cast iron and ductile iron.

Connection mode: flange connection

Design standard: GB/T12221

Length standard: GB/T9113, JB/T79

Test standards: JB/T9092, GB/T13927

Product overview

Rubber flap check valve, also known as rubber flap check valve, is mainly composed of valve body, bonnet and flap. Among them, the rubber valve is made of steel plate as the pressure-bearing part and reinforced nylon cloth as the substrate, the outer layer is made of thermal vulcanization integral encapsulation technology, and the valve seat is made of ceramic spraying technology to prolong the service life of the valve. The valve adopts the whole basin design, and has the characteristics of small head loss, difficult accumulation of sundries and simple maintenance. The valve is mainly suitable for water supply and drainage system.

Product features

Due to the small closing stroke, the rubber flap check valve can be fully opened with a stroke angle of only 35 degrees, and the closing speed is fast. It can be installed at the water outlet of the water pump. For large caliber, the buffer cylinder device can be selected, of which 85%-90% stroke is fast closing and 10%-15% stroke is slow closing. The slow closing time can be adjusted from 1 to 15 seconds, and there is no indication of the opening and closing position of the oil cylinder to reduce the damage of the water hammer to the pump.

Material of main parts

Part Name | Body | Cap | Disc |

Material | Cast iron | Cast iron | Steel + reinforced nylon cloth |

Main performance specifications

Model | Nominal pressurePN(MPa) | Seal test pressure(MPa) | Shell test pressure(MPa) | Maximum working pressure(MPa) | Medium insulation |

HC44X-10 | 1.0 | 1.1 | 1.5 | 1.0 | 0-80℃ |

HC44X-16 | 1.6 | 1.76 | 2.4 |

|

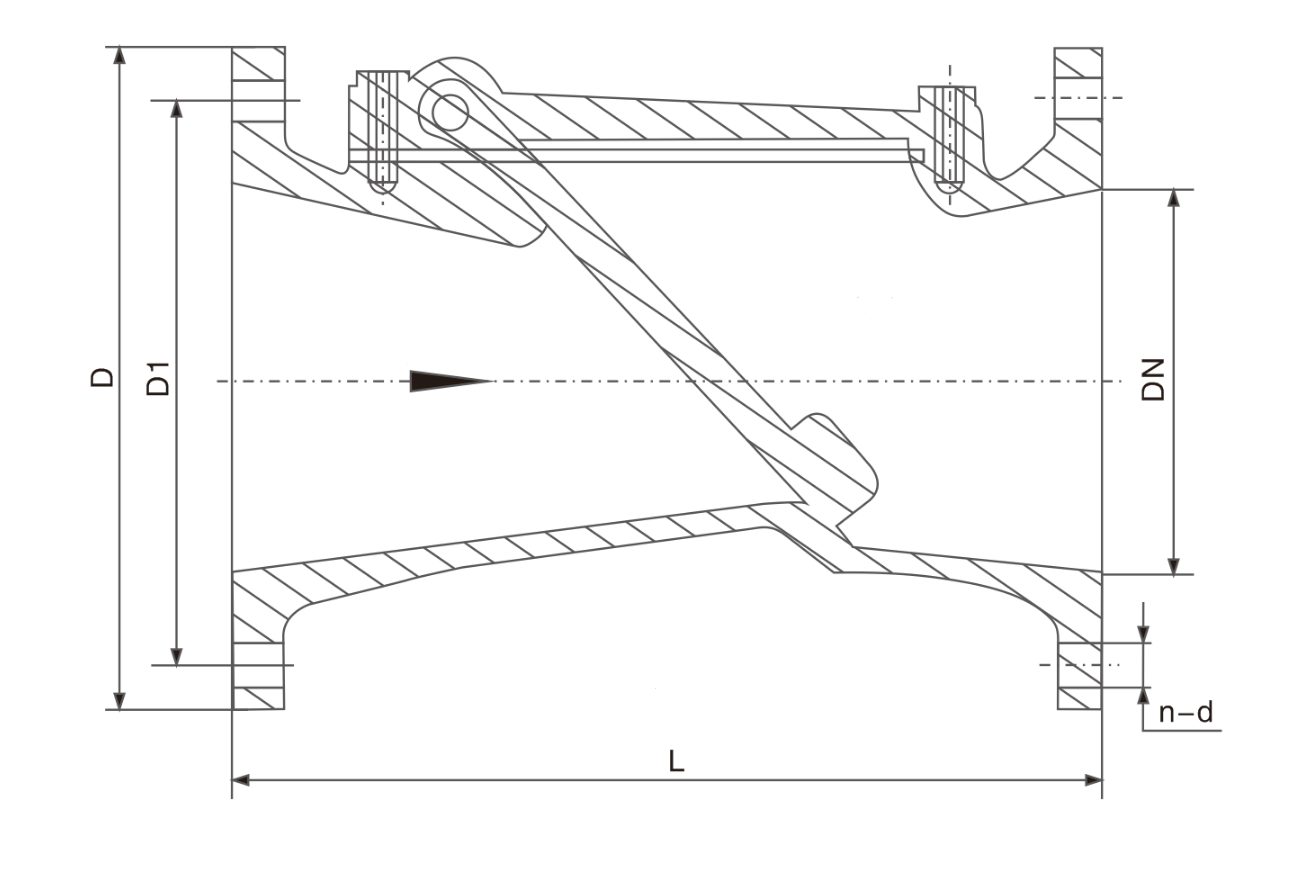

Main dimensions

Model | DN | L | D | D1 | dn | n |

HC44X-10/16 | 50 | 203 | 165 | 125 | 17.5 | 4 |

65 | 216 | 185 | 145 | 17.5 | 4 | |

80 | 241 | 200 | 160 | 17.5 | 8 | |

100 | 292 | 220 | 180 | 17.5 | 8 | |

150 | 356 | 285 | 240 | 22 | 8 | |

200 | 495 | 240 | 295 | 22 | 8 | |

250 | 622 | 395 | 350 | 22 | 12 | |

300 | 698 | 445 | 400 | 22 | 12 | |

350 | 787 | 505 | 460 | 22 | 16 | |

400 | 914 | 565 | 515 | 22 | 16 | |

450 | 978 | 615 | 565 | 26 | 20 | |

500 | 978 | 670 | 620 | 26 | 20 | |

600 | 1295 | 780 | 725 | 30 | 20 |

Jing12011202000600

Jing12011202000600