Product overview

The Electric wafer midline butterfly valve adopts an integrated structure, which can be controlled by connecting to 220V AC power supply, or it can be added to a control module and input control signals (4-20mDC or 1-5V DC) for adjustment and control. The valve has the advantages of strong function, small volume, reliable performance, simple matching and large circulation capacity. Especially suitable for occasions where the medium is viscous, contains particles and fibers. The valve plate and soft seal (rubber ring and tetrafluoroethylene ring) can be used to reduce leakage (up to 0.01%), and triple eccentric hard seal valve body can be used under high temperature and high pressure conditions. It is widely used in the industrial process automatic control system of food, environmental protection, light industry, petroleum, chemical industry, teaching equipment, paper making, electric power and other industries.

Product features

1. Electric opening and closing, with functions of arbitrary adjustment, check and cut-off, convenient operation, safety and reliability.

2. The flow resistance is small, and the flow resistance coefficient is less than 0.3 when the valve is fully open.

3. When an accident or power failure occurs, the butterfly valve can be controlled by manual operation.

4. Slow opening, fast opening, fast closing and slow closing can be realized continuously, and the backflow of pump outlet medium and water hammer can be effectively prevented.

5. Energy-saving driving the same driving motor as ordinary butterfly valves can realize the functions of high-speed small torque in fast closing section and high torque in slow closing low section.

Main technical parameters

Nominal diameter DN(mm) | 50~1200 |

| Nominal pressure | PN0.6、1.0、1.6、2.5MPa |

| Type of attachment | Double clip type |

| Valve plate form | Vertical plate type |

| Discharge characteristic | Approximate quick-opening type |

| Range of action | 0~90° |

| Leakage quantity | According to GB/T4213-92, it is 10-4 of the Kv value, soft seal: zero leakage |

| Intrinsic error | ±2.5% |

| Return difference | ±2.5% |

| Dead space | 1% (Adjustable) |

| Adjustable extent | 50:1 |

| Configure the actuator | It can be equipped with PSQ, HQ, UNIC, 361RS, HR and other series of angular stroke electric actuators. |

| Control mode | Switch-in-place lamp (switch two-position control), intelligent adjustment (4 ~ 20mA analog signal control) |

Main parts materials

| Part name | Material |

| Body | Nodular cast steel, cast steel, alloy steel, stainless steel |

| Butterfly plate | Gray cast iron, nodular cast steel, cast steel, stainless steel and special materials. |

| O-ring | All kinds of rubber, PTFE |

| Valve rod | 2Cr13、Stainless steel |

| Filling | O-ring, flexible graphite |

Main performance specifications

| Nominal diameter DN(mm) | DN50~1200 | ||||

| nominal pressure | PN(MPa) | 0.6 | 1.0 | 1.6 | 2.5 |

| Testing pressure | Strength test | 0.9 | 1.5 | 2.4 | 3.75 |

| Pressure test | 0.66 | 1.1 | 1.76 | 2.75 | |

| Low pressure airtight test | 0.5~0.7 | ||||

| Applicable medium | Air, water, sewage, steam, gas, oil, etc. | ||||

| Design standards | GB/T2238-1989 |

| Flange connection size | GB/T9113.1-2000;GB/T9115.1-2000;JB78 |

| Structure length | GB/T12221-1989 |

| Pressure testing | GB/T13927-2000;JB/T9092-1999 |

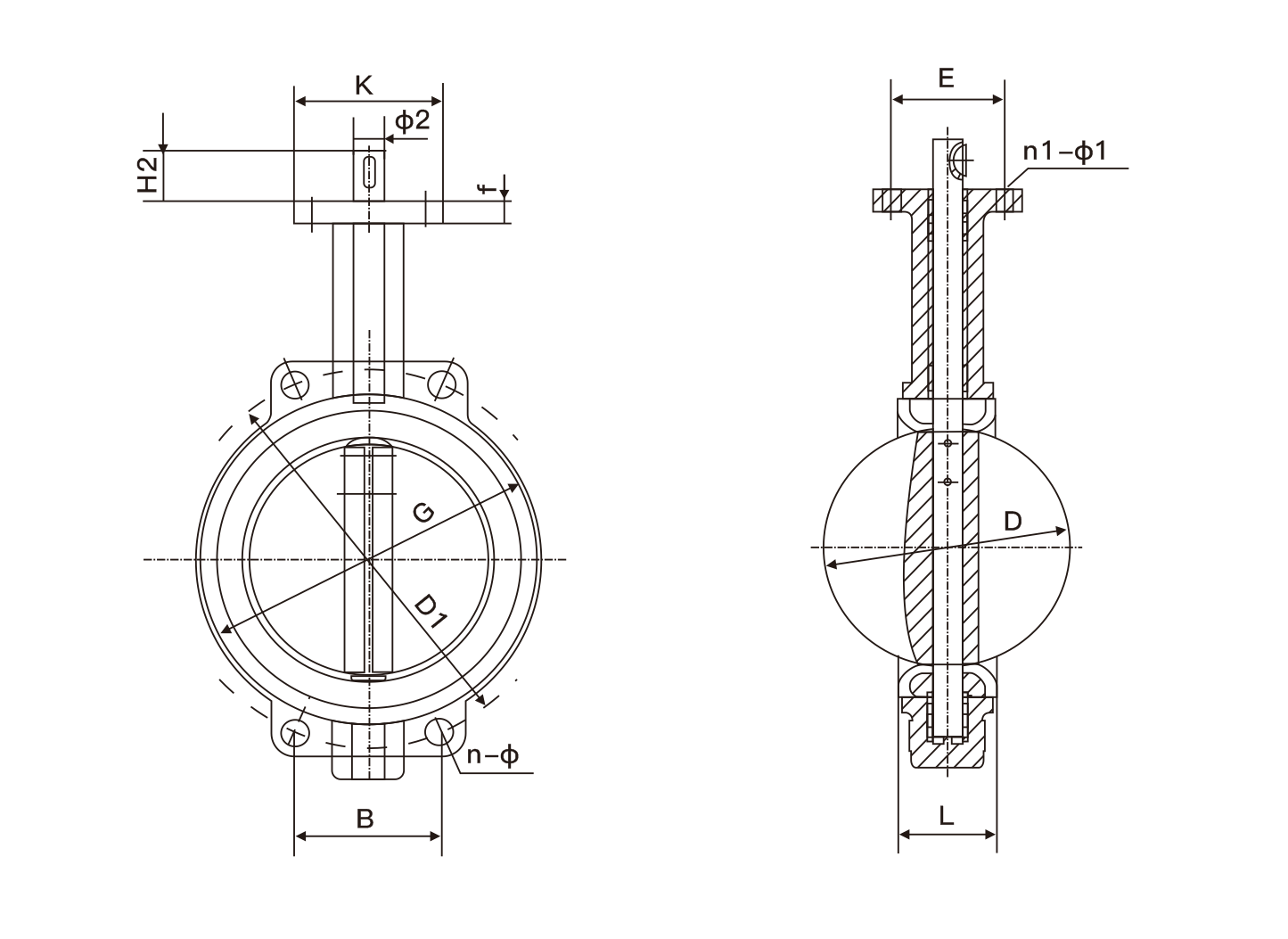

Main dimensions and weight(PN1.0/1.6MPa)

| DN(mm) | A | B | L | D1 | n-Φ | K | E | 4-Φ1 | Φ2 | G | WT(kg) |

| 50 | 140 | 80 | 43 | 125 | 4-19 | 77 | 57.15 | 4-6.7 | 12.6 | 100 | 3.34 |

| 65 | 152 | 89 | 46 | 145 | 4-19 | 77 | 57.15 | 4-6.7 | 12.6 | 120 | 3.94 |

| 80 | 159 | 95 | 45.21 | 160 | 8-19 | 77 | 57.15 | 4-6.7 | 12.6 | 127 | 4.05 |

| 100 | 178 | 114 | 52.07 | 180 | 8-19 | 92 | 69.85 | 4-10.3 | 15.77 | 156 | 5.48 |

| 125 | 190 | 127 | 55.5 | 210 | 8-19 | 92 | 69.85 | 4-10.3 | 18.92 | 190 | 7.66 |

| 150 | 203 | 139 | 55.75 | 240 | 8-23 | 92 | 69.85 | 4-10.3 | 18.92 | 212 | 8.5 |

| 200 | 238 | 175 | 60.58 | 295 | 8-23 | 115 | 88.9 | 4-14.3 | 22.1 | 268 | 25 |

| 250 | 268 | 203 | 68 | 350 | 12-23 | 115 | 88.9 | 4-14.3 | 28.45 | 325 | 31.4 |

| 300 | 306 | 242 | 76.9 | 400 | 12-23 | 140 | 107.95 | 4-14.3 | 31.6 | 403 | 45.9 |

| 350 | 368 | 267 | 76.17 | 460 | 16-23 | 140 | 107.95 | 4-14.3 | 31.6 | 436 | 54 |

Jing12011202000600

Jing12011202000600