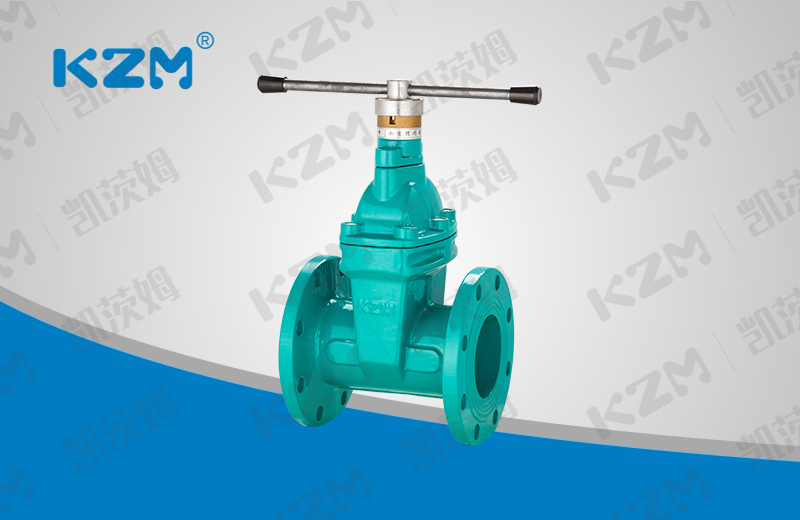

Mechanical locking soft seal gate valve

Product overview

Product model: RVLX-10/16

Nominal pressure: PN1.0MPa/1.6MPa

Nominal diameter: 40 ~ 40~400mm

Sealing test pressure: 1.1MPa/1.76MPa

Strength test pressure: 1.5MPa/2.4MPa

Applicable temperature: ≤120℃

Applicable media: water, oil, plumbing and other non-corrosive fluids.

Driving mode: manual

Product overview

RVLX Mechanical locking soft seal gate valve is made of special components, based on probability, and magnetic pole coding by computer. Anti-theft valve is an effective management means for some units or individuals to use water recklessly, refuse to pay water charges, steal water and even destroy pipeline valves. At the user terminal of water, gas and other pipelines, the management department needs to strengthen the control of the valves in front of the measuring instruments. The valve has the anti-theft function. The flange anti-theft valve can be self-locked at any position of the switch. The flange anti-theft valve can only be opened and closed with the equipped tools.

Product features

RVLX Mechanical locking soft seal gate valve achieves a good sealing effect by using the deformation compensation function generated by the integral rubber coating of the gate valve, which overcomes the phenomena of poor sealing, water leakage and rust of general gate valves. The bottom adopts the same flat-bottom valve seat design as the water pipe, which does not generate debris deposition, has small flow resistance coefficient and smooth passage. The inside and outside of the valve body are coated with epoxy resin to prevent corrosion and rust, which can be used not only for domestic water, but also for sewage treatment system. It is widely used as a regulating and throttling device in tap water, sewage, construction, petrochemical industry, food, medicine, light textile, electric power, ship, metallurgical energy system and other fluid pipelines.

Main outline connection dimensions

Nominal diameter DN | Main connection size (mm) | ||||||

L | D | D1 | D2 | b | Z-φd | H | |

40 | 200 | 145 | 110 | 85 | 16 | 4-φ18 | 290 |

50 | 250 | 160 | 125 | 100 | 16 | 4-φ18 | 320 |

65 | 265 | 180 | 145 | 120 | 18 | 4-φ18 | 350 |

80 | 280 | 195 | 160 | 135 | 20 | 8-φ18 | 380 |

100 | 300 | 215 | 180 | 155 | 20 | 8-φ18 | 400 |

125 | 325 | 245 | 210 | 185 | 22 | 8-φ18 | 450 |

150 | 350 | 280 | 240 | 210 | 24 | 8-φ23 | 530 |

200 | 400 | 335 | 295 | 265 | 26 | 12-φ23 | 580 |

250 | 450 | 405 | 355 | 320 | 30 | 12-φ25 | 670 |

300 | 500 | 460 | 410 | 375 | 30 | 12-φ25 | 90 |

Jing12011202000600

Jing12011202000600