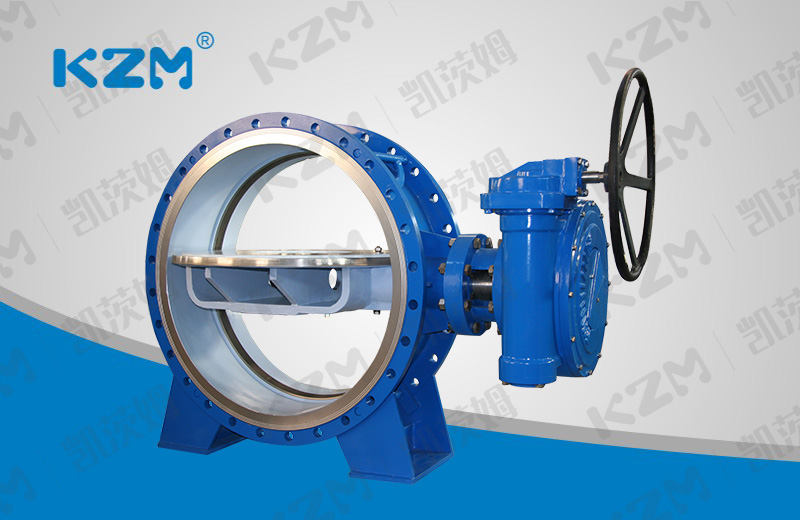

Two-way hard seal butterfly valve

Product overview

Product model: DS343H

Nominal diameter: DN50-DN2000 (mm)

Applicable temperature: carbon steel: -29℃~425℃ stainless steel: -40℃~600℃

Applicable medium: air, water, steam, gas, oil, acid, alkali, salt with weak corrosive medium, etc.

Main material: cast steel, stainless steel, ductile iron

Design and manufacturing: GB/T 12238, JB/T8527

Structure length: GB/T12221

Test and inspection: GB/T13927

Product description

The two-way hard-sealed butterfly valve is optimized by our technical staff after absorbing the structure and characteristics of similar foreign products and overcoming the defects of the original products in use, so that it has a more durable life and a more reliable seal.

The butterfly valve adopts the three-dimensional eccentric design principle. The sealing pair is composed of two overlapping cone oblique sections. After the eccentric value of the valve body and valve seat, the rotation center of the butterfly plate realizes instant contact and separation of opening and closing, and is composed of the butterfly plate. The metal and graphite laminated structure of the sealing ring realizes the labyrinth seal, which can not only reduce the valve switching torque but also ensure the sealing performance of the butterfly valve. Realize the two-way sealing and zero leakage of the butterfly valve inlet and outlet.

Features

1. Adopting an oblique elliptical butterfly plate radial dynamic balance sealing system, the force on both sides of the valve inlet and outlet is approximately balanced, the opening torque of the valve is small, the forward and reverse sealing performance is reliable, and the two-way pressure can reach 100%;

2. The valve sealing surface adopts an integral metal sealing ring, which is processed by high-precision machining. The sealing section is oval, which forms a sealing pair with the metal sealing surface of the valve seat. When the valve is opened and closed, the sealing surface of the butterfly plate touches or detaches instantly at various points along the 360o circumference, which can quickly and accurately realize the opening or closing action;

3. The triple eccentric structure is adopted, that is, a sealing cone angle eccentricity is added on the basis of the double eccentric butterfly valve.

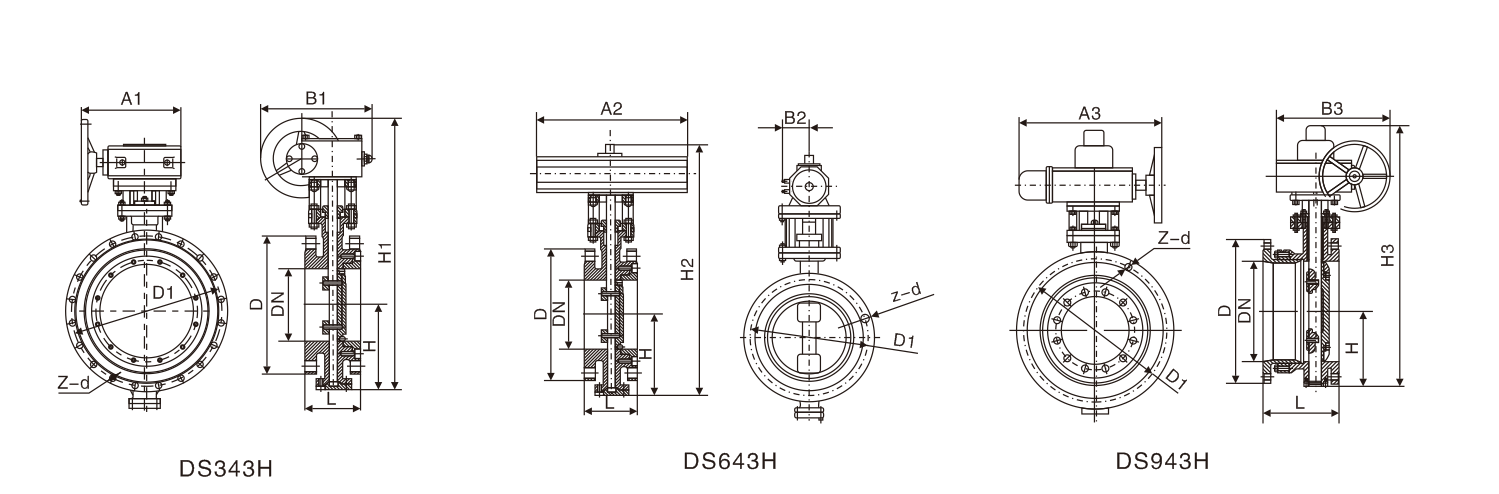

Main external connection size

Nominal diameter DN | Structure length (standard value) | Dimensions (reference value) | Connection size (standard value) | ||||||||||||||||||

| L | H | DS343H | DS643H | DS943H | PN0.6MPa | PN1.0MPa | |||||||||||||||

| mm | in | Short | Long | H1 | A1 | B1 | H2 | A2 | B2 | H3 | A3 | B3 | D | D1 | Z-d | D | D1 | Z-d | |||

| 40 | 1 1/2 | 106 | 140 | 107 | 330 | 180 | 200 | 605 | 245 | 72 | 530 | 250 | 255 | 130 | 100 | 4-14 | 150 | 110 | 4-18 | ||

| 50 | 2 | 108 | 150 | 112 | 350 | 180 | 200 | 625 | 245 | 72 | 530 | 250 | 255 | 140 | 110 | 4-14 | 165 | 125 | 4-18 | ||

| 65 | 2 1/2 | 112 | 170 | 115 | 370 | 180 | 200 | 645 | 245 | 72 | 530 | 250 | 255 | 160 | 130 | 4-14 | 185 | 145 | 4-18 | ||

| 80 | 3 | 114 | 180 | 120 | 380 | 180 | 200 | 675 | 355 | 92 | 565 | 250 | 255 | 190 | 150 | 4-18 | 200 | 160 | 8-18 | ||

| 100 | 4 | 127 | 190 | 138 | 420 | 180 | 200 | 715 | 355 | 92 | 600 | 250 | 255 | 210 | 170 | 4-18 | 220 | 180 | 8-18 | ||

| 125 | 5 | 140 | 200 | 164 | 460 | 180 | 200 | 800 | 355 | 92 | 640 | 250 | 255 | 240 | 200 | 8-18 | 250 | 210 | 8-18 | ||

| 150 | 6 | 140 | 210 | 175 | 555 | 270 | 280 | 850 | 250 | 170 | 705 | 300 | 315 | 265 | 225 | 8-18 | 285 | 240 | 8-22 | ||

| 200 | 8 | 152 | 230 | 200 | 760 | 400 | 425 | 925 | 250 | 170 | 775 | 300 | 315 | 320 | 280 | 8-18 | 340 | 295 | 8-22 | ||

| 250 | 10 | 165 | 250 | 243 | 830 | 400 | 425 | 1035 | 450 | 220 | 945 | 300 | 315 | 375 | 335 | 12-18 | 395 | 350 | 12-22 | ||

| 300 | 12 | 178 | 270 | 250 | 895 | 450 | 560 | 1070 | 450 | 220 | 1070 | 300 | 315 | 440 | 395 | 12-22 | 445 | 400 | 12-22 | ||

| 350 | 14 | 190 | 290 | 280 | 950 | 450 | 560 | 1190 | 450 | 280 | 1140 | 300 | 315 | 490 | 445 | 12-22 | 505 | 460 | 16-22 | ||

| 400 | 16 | 216 | 310 | 305 | 1190 | 535 | 580 | 1250 | 650 | 280 | 1210 | 300 | 315 | 540 | 495 | 16-22 | 565 | 515 | 16-26 | ||

| 450 | 18 | 222 | 330 | 350 | 1255 | 535 | 580 | 1295 | 650 | 280 | 1335 | 575 | 714 | 595 | 550 | 16-22 | 615 | 565 | 20-26 | ||

| 500 | 20 | 229 | 350 | 380 | 1305 | 535 | 580 | 1455 | 850 | 380 | 1415 | 575 | 714 | 645 | 600 | 20-22 | 670 | 620 | 20-26 | ||

| 600 | 24 | 267 | 390 | 445 | 1340 | 570 | 660 | 1585 | 850 | 380 | 1605 | 656 | 810 | 755 | 705 | 20-26 | 780 | 725 | 20-30 | ||

| 700 | 28 | 292 | 430 | 480 | 1520 | 750 | 550 | 1700 | 1250 | 380 | 1844 | 656 | 810 | 860 | 810 | 24-26 | 895 | 840 | 24-30 | ||

| 800 | 32 | 318 | 470 | 530 | 1710 | 750 | 550 | 1865 | 1250 | 380 | 2040 | 656 | 810 | 975 | 920 | 24-30 | 1015 | 950 | 24-33 | ||

| 900 | 36 | 330 | 510 | 580 | 1810 | 750 | 550 | 2015 | 1500 | 580 | 2255 | 785 | 863 | 1075 | 1020 | 24-30 | 1115 | 1050 | 28-33 | ||

| 1000 | 40 | 410 | 550 | 650 | 1960 | 900 | 750 | 2226 | 1500 | 580 | 2380 | 785 | 863 | 1175 | 1120 | 28-30 | 1230 | 1160 | 28-36 | ||

| 1200 | 48 | 470 | 630 | 760 | 2250 | 1000 | 925 | - | - | - | 2640 | 785 | 863 | 1405 | 1340 | 32-34 | 1455 | 1380 | 32-39 | ||

| 1400 | 56 | 530 | 710 | 850 | 2435 | 1000 | 925 | - | - | - | 2886 | 810 | 890 | 1630 | 1560 | 36-34 | 1675 | 1590 | 36-42 | ||

| 1600 | 64 | 600 | 790 | 1030 | 2780 | 1000 | 925 | - | - | - | 3156 | 810 | 890 | 1830 | 1760 | 40-34 | 1915 | 1820 | 40-48 | ||

| 1800 | 72 | 670 | 870 | 1230 | 3020 | 1100 | 980 | - | - | - | 3421 | 830 | 930 | 2045 | 1970 | 44-41 | 2115 | 2020 | 44-48 | ||

| 2000 | 80 | 760 | 950 | 1350 | 3270 | 1100 | 980 | - | - | - | 3685 | 830 | 940 | 2265 | 2180 | 48-48 | 2325 | 2230 | 48-48 | ||

| 2200 | 88 | - | 1000 | 1450 | 3470 | 1200 | 1050 | - | - | - | 3885 | - | - | 2475 | 2390 | 52-48 | 2550 | 2440 | 52-56 | ||

| 2400 | 96 | - | 1100 | 1550 | 3670 | 1200 | 1050 | - | - | - | 4055 | - | - | 2685 | 2600 | 56-48 | 2760 | 2670 | 56-56 | ||

| 2600 | 104 | - | 1200 | 1650 | 3870 | 1300 | 1120 | - | - | - | 4260 | - | - | 2905 | 2810 | 60-54 | 2960 | 2850 | 60-56 | ||

| 2800 | 112 | - | 1300 | 1750 | 4080 | 1300 | 1120 | - | - | - | 4490 | - | - | 3115 | 3020 | 64-54 | 3180 | 3070 | 64-56 | ||

| 3000 | 120 | - | 1400 | 1850 | 4280 | 1400 | 1190 | - | - | - | 4690 | - | - | 3315 | 3220 | 68-54 | 3405 | 3290 | 68-62 | ||

Jing12011202000600

Jing12011202000600