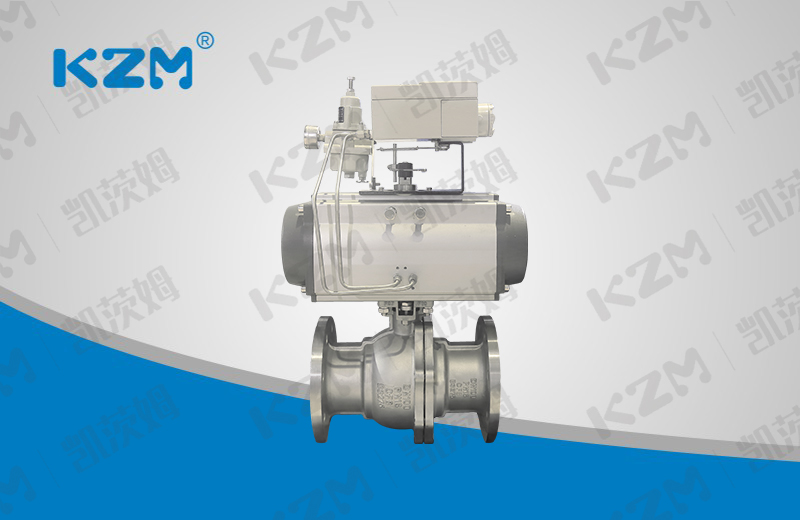

Pneumatic floating ball valve

Product overview

Product model: Q641F/H/Y

Nominal diameter: DN15~200mm

Nominal pressure: PN1.6~10.0MPa

Working temperature: -196~150℃

Main material: CF8, WCB, A216-WCB

Design standard: GB/T 12237, API 6D, ASME B16.34

Connecting flange: GB/T 9113, JB/T79, HG20592, ANSI B16.5, B16.47

Test and inspection: GB/T9092, API6D, API598

Product description

The diameter of the valve body channel and the connecting pipe of the pneumatic floating ball valve are equal and form the same diameter, and the medium can flow through almost without loss. Products are usually used in occasions with strict sealing requirements. In addition to controlling gas, liquid, and vaporized media, they are also suitable for controlling sewage and media containing fibrous impurities. They are widely used in petroleum, chemical, metallurgy, light industry, papermaking, power stations, Work areas such as refrigeration.

Features

1. The O-type floating ball valve adopts full-diameter or reduced-diameter design, with low flow resistance.

2. The valve adopts a high platform structure and ISO5211 connection standard, which can make the installation of electric/pneumatic actuators more professional.

3. The valve stem adopts the built-in type, the shaft shoulder and the PTFE (or reinforced graphite) thrust pad structure prevent the valve stem from blowing out due to the pressure in the pipeline, and the PTFE (or reinforced graphite) material reduces the opening and closing of the valve Torque makes the operation more labor-saving.

4. It has a fire-proof and anti-static structure. Conductive springs are set between the valve stem and the valve body and between the valve stem and the ball to avoid ignition of flammable media due to static electricity. Ensure system security.

5. The fire-resistant structure is double protected. In case of fire and the sealing ring is burnt out, each sealing part of the ball valve can form a metal-to-metal hard sealing structure.

Material of main parts

| Serial number | Part Name | Material | |

| GB | ASTM | ||

| 1 | Body | CF8 | A2116-WCB |

| 2 | Sealing ring | PTFE | PTFE |

| 3 | Sphere | 1C18Ni9Ti | SS304 |

| 4 | Nut | 35 | A194-2H |

| 5 | Stud | 35CrMoA | A193-B7 |

| 6 | Stone body | WCB | A216-WCB |

| 7 | Gasket | Flexible graphite + stainless steel | B12.10-304F/.G |

| 8 | Packing | PTFE | PTFE |

| 9 | Packing gland | WCB | A2116-WCB |

| 10 | Positioning pieces | 25 | A105 |

| 11 | Retaining ring | 65Mn | AISI 1066 |

| 12 | Handle | K33 | A47-667 Gr.32510 |

| 13 | Stem | 1Cr33 | A276-410 |

| 14 | Screw | 35 | A193-B7 |

| 15 | Thrust washer | PTFE | PTFE |

Main technical specifications

| Nominal diameter DN (mm) | 15-200 | |||

| Nominal pressure PN (MPa) | 1.6 | |||

| Nominal pressure PS (MPa) | Strength test | 2.4 | ||

| Sealing test | 1.76 | |||

| Material\Material Code | C | P | R | |

| main part | Valve body | WCB | ZG1Cr18Ni9Ti | ZG0Cr18Ni12Mo2Ti |

| Butterfly board | 2CR13 | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti | |

| Stem | 2CR13 | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti | |

| Sealing ring | Reinforced polytetrafluoroethylene p-polyphenylene | |||

| filler | PTFE Flexible Graphite | |||

| Applicable working conditions | Applicable medium | Water, steam, oil | Nitric acid | Acetic acid |

| proper temperature | -28℃~300℃ | |||

| Actuator | model | BAW series, GT series, SW series | ||

| Air pressure | 0.4-0.7MPA | |||

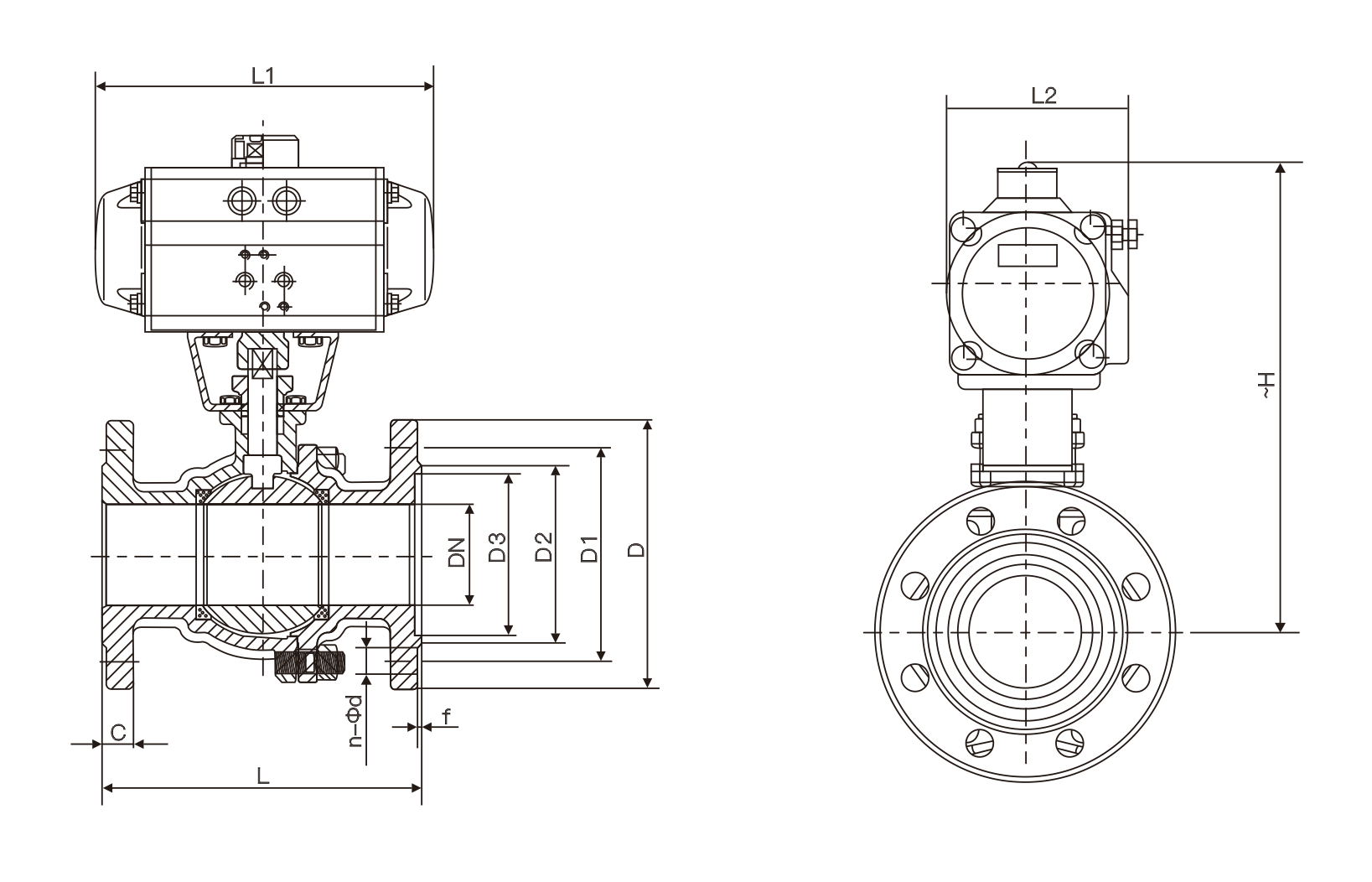

Main external connection size

| Nominal diameter DN (mm) | Dimensions | Connection flange size | ||||||||

| L | L1 | L2 | H | D | D1 | D2 | C | f | n-Φd | |

| 15 | 130 | 141/159 | 71/83 | 204/235 | 95 | 65 | 45 | 16 | 2 | 4-Φ14 |

| 20 | 130 | 141/159 | 71/83 | 209/240 | 105 | 75 | 58 | 18 | 2 | 4-Φ14 |

| 25 | 140 | 159/211 | 83/95 | 214/256 | 115 | 85 | 68 | 18 | 2 | 4-Φ14 |

| 32 | 165 | 159/248 | 83/107 | 257/277 | 140 | 100 | 78 | 18 | 2 | 4-Φ18 |

| 40 | 165 | 211/248 | 95/107 | 274/292 | 150 | 110 | 88 | 18 | 3 | 4-Φ18 |

| 50 | 203 | 248/269 | 107/123 | 290/300 | 165 | 125 | 102 | 18 | 3 | 4-Φ18 |

| 65 | 222 | 248/315 | 107/141 | 310/335 | 185 | 145 | 122 | 18 | 3 | 4-Φ18 |

| 80 | 241 | 269/345 | 123/152 | 346/368 | 200 | 160 | 138 | 20 | 3 | 8-Φ18 |

| 100 | 305 | 345/409 | 152/172 | 378/410 | 220 | 180 | 158 | 20 | 3 | 8-Φ18 |

| 125 | 356 | 409/550 | 172/215 | 425/450 | 250 | 210 | 188 | 22 | 3 | 8-Φ18 |

| 150 | 394 | 550/600 | 215/240 | 468/531 | 285 | 240 | 212 | 22 | 3 | 8-Φ22 |

| 200 | 457 | 600/633 | 240/262 | 583/618 | 340 | 295 | 268 | 24 | 3 | 12-Φ22 |

Jing12011202000600

Jing12011202000600