Two-way flow hard-touch hard-sealed rotary ball valve

Product overview

Product model: GWXDF3204Y

Nominal diameter: DN50-DN3000mm

Nominal pressure: PN0.6-4.0MPa

Applicable medium: clean water, sewage, oil, etc.

Medium temperature: 0~+80℃

Body material: carbon steel, cast iron

Design standard: GB/T12237

Structure length: GB/T12221

Pressure test: GB/T13927

Product description

Two-way flow hard-on-hard seal rotary ball valves are widely used in water pump outlets and pipe network systems, especially in mesh and ring pipe networks such as municipal and fire fighting. For such two-way flow conditions, one valve is equivalent to two ordinary one-way sealed valves , Has a very high cost performance. It can be applied to the opening and closing and adjustment of pipe network system media in metallurgy, petrochemical, electric power, chemical, environmental protection, municipal and other industries.

Features

1. Adaptive function: When the two-way pressure-bearing spherical rotary valve is closed, the valve seat can automatically find the coincidence center, eliminate the coincidence error due to impurity retention or processing, assembly accuracy and other factors, and automatically move to the best position to achieve Well sealed.

2. Automatically compensate for wear: When the sealing surface of the two-way pressure-bearing spherical rotary valve is worn for a long time, because the sealing surface is a linear seal, the function of the spherical surface and the conical surface is equivalent to the function of the obtuse-angle cutting tool and the cutting board, and the pressure of the medium Form an embedded rolling seal, which can automatically bridge wear or damage.

3. Low sealing friction during opening and closing: the sealing surface of the valve plate is a spherical surface, and the rotation center of the valve shaft deviates from the center of the spherical surface. The friction between the valve plate and the sealing surface of the valve seat is extremely small, and the service life is long.

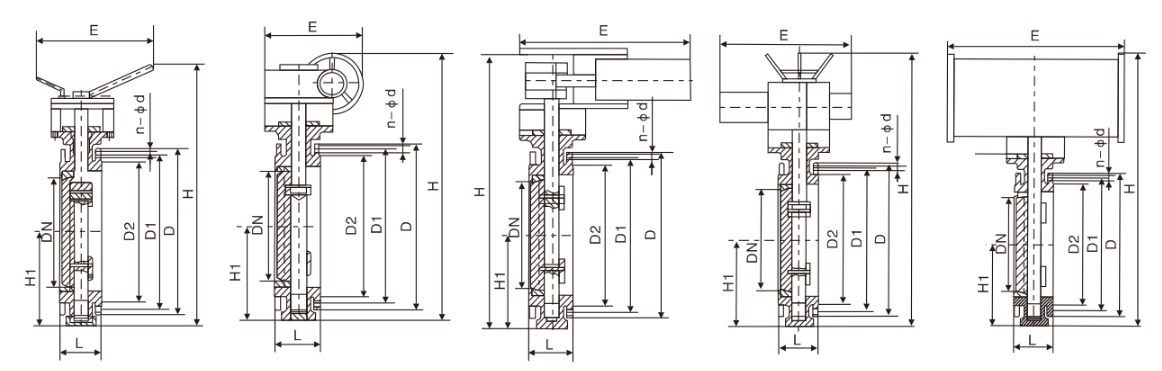

Main external connection size

| DN | A | B | C | D | E | H | L | N-φD | ||||||

| Manual | Pneumatic | Electric | Manual | Pneumatic | Electric | Clip-on | Flange type | Clip-on | Flange type | |||||

| 50 | 88 | 110 | 140 | 112 | 200 | 245 | 255 | 350 | 625 | 530 | 43 | 108 | 4-14 | 4-14 |

| 55 | 108 | 130 | 160 | 115 | 200 | 245 | 255 | 370 | 625 | 530 | 46 | 112 | 4-14 | 4-14 |

| 80 | 124 | 150 | 190 | 120 | 200 | 245 | 255 | 380 | 645 | 565 | 64 | 114 | 4-18 | 4-18 |

| 100 | 144 | 170 | 210 | 138 | 200 | 355 | 255 | 420 | 675 | 600 | 64 | 127 | 4-18 | 4-18 |

| 125 | 174 | 200 | 240 | 164 | 200 | 355 | 255 | 460 | 715 | 640 | 70 | 140 | 4-18 | 8-18 |

| 150 | 199 | 225 | 265 | 175 | 280 | 355 | 315 | 555 | 800 | 705 | 76 | 140 | 4-18 | 8-18 |

| 200 | 254 | 280 | 320 | 200 | 425 | 250 | 315 | 760 | 850 | 775 | 89 | 152 | 4-18 | 8-18 |

| 250 | 309 | 335 | 375 | 230 | 425 | 250 | 315 | 830 | 925 | 945 | 114 | 165 | 4-18 | 12-18 |

| 300 | 363 | 395 | 440 | 260 | 560 | 450 | 315 | 895 | 1035 | 1070 | 114 | 178 | 4-22 | 12-22 |

| 350 | 413 | 445 | 490 | 300 | 560 | 450 | 315 | 950 | 1070 | 1140 | 127 | 190 | 4-22 | 12-22 |

| 400 | 463 | 495 | 540 | 340 | 580 | 450 | 315 | 1190 | 1190 | 1210 | 140 | 216 | 4-22 | 16-22 |

| 450 | 518 | 550 | 595 | 350 | 580 | 650 | 714 | 1255 | 1250 | 1355 | 152 | 222 | 4-22 | 16-22 |

| 500 | 568 | 600 | 645 | 380 | 580 | 650 | 714 | 1305 | 1290 | 1415 | 152 | 229 | 4-22 | 20-22 |

| 600 | 667 | 705 | 755 | 450 | 660 | 850 | 810 | 1340 | 1455 | 1605 | 178 | 267 | 4-M24 | 20-26 |

| 700 | 772 | 810 | 860 | 480 | 550 | 850 | 810 | 1520 | 1585 | 1844 | 229 | 292 | 4-M24 | 24-26 |

| 800 | 878 | 920 | 975 | 530 | 550 | 1250 | 810 | 1710 | 1700 | 2040 | 241 | 318 | 4-M27 | 24-30 |

| 900 | 978 | 1020 | 1075 | 580 | 550 | 1250 | 863 | 1810 | 1965 | 2255 | 241 | 330 | 4-M27 | 24-30 |

| 1000 | 1078 | 1120 | 1175 | 650 | 750 | 1250 | 863 | 1960 | 2015 | 2380 | 300 | 410 | 4-M27 | 28-30 |

| 1200 | 1295 | 1340 | 1405 | 760 | 925 | 1250 | 863 | 2250 | 2250 | 2640 | 350 | 470 | 4-M30 | 32-33 |

| 1400 | 1510 | 1560 | 1630 | 850 | 925 | 1250 | 1055 | 2434 | 2550 | 2866 | 390 | 530 | 4-M33 | 36-36 |

| 1600 | 1710 | 1760 | 1830 | 1030 | 925 | 1250 | 1055 | 2780 | 2750 | 3166 | 420 | 600 | 4-M33 | 40-36 |

| 1800 | 1918 | 1970 | 2045 | 1230 | 980 | 1250 | 1183 | 3020 | 2950 | 3421 | 480 | 670 | 4-M36 | 44-39 |

| 2000 | 2125 | 2180 | 2265 | 1350 | 980 | 1500 | 1286 | 3270 | 3350 | 3685 | 540 | 760 | 4-M39 | 48-42 |

| 2200 | 2340 | 2400 | 2485 | 1300 | - | - | - | - | - | - | 580 | 800 | 4-M39 | 52-42 |

| 2400 | 2540 | 2600 | 2685 | 1400 | - | - | - | - | - | - | 620 | 850 | 4-M39 | 56-42 |

| 2600 | 2740 | 2810 | 2905 | 1500 | - | - | - | - | - | - | 650 | 900 | 4-M45 | 60-48 |

| 2800 | 2960 | 3020 | 3115 | 1610 | - | - | - | - | - | - | 700 | 950 | 4-M45 | 64-48 |

| 3000 | 3160 | 3220 | 3315 | 1720 | - | - | - | - | - | - | 700 | 1000 | 4-M45 | 68-48 |

Jing12011202000600

Jing12011202000600