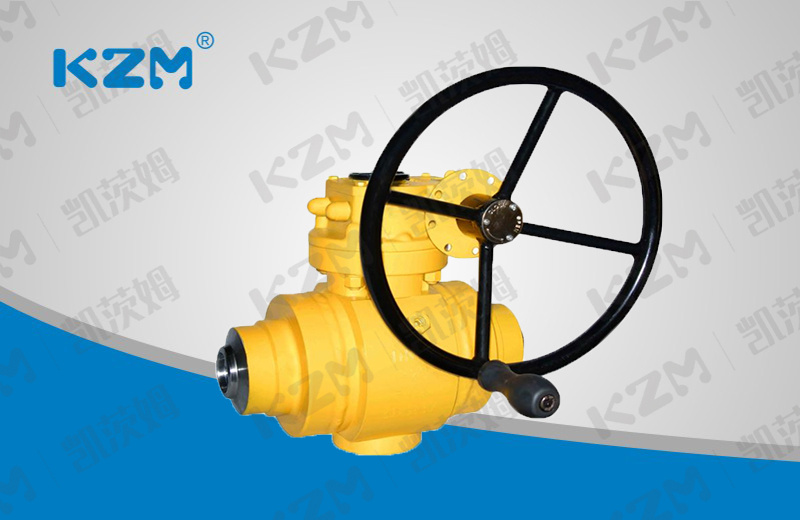

American standard fixed welded ball valve

Product overview

Valve model: Q367F

Connection method: welding, butt welding

Pressure rating: Class 150~1500Lb

Product specifications: NPS 2"~56"

Product material: WCB, A105, F11, F22, F304, F316, CF8, CF8M, WCC or according to customer requirements

Applicable temperature: -25℃≤t≤200 ℃

Applicable medium: water, air, oil and other fluids that do not chemically react with carbon steel, etc.

Drive mode: manual

Product description

American standard fully welded ball valves are widely used in various fields. Its superior quality and high performance stability cannot be achieved by ordinary cast steel ball valves. Its service life is much longer than that of cast steel ball valves. This product is widely used in city gas. , Central heating, heat exchangers, petrochemicals, shipbuilding, steel plants, pressure regulating stations, power plants and other pipeline equipment, this product can be used reliably for a long time, without maintenance, and simple to install.

Scope of application

City gas: gas output pipeline, main line and various branch supply pipelines, etc. Centralized heating: output pipelines, main lines, and branch lines of large-scale heating equipment. Heat exchanger: the pipeline and each circuit are opened and closed. Iron and steel plants: various fluid pipelines, exhaust gas discharge channels, gas and heat supply pipelines, fuel supply pipelines, etc. All kinds of industrial equipment: all kinds of heat treatment pipelines, all kinds of industrial gas and heating pipelines.

Product Features

The American standard fully welded ball valve is a worm gear drive. The valve body is made of seamless steel pipe. The overall structure adopts a fully welded manufacturing process. The valve seat is composed of a PTFE sealing ring and a spring. It has a strong ability to adapt to changes in pressure and temperature. , There will be no leakage in the scope of use. The processing process of the sphere of this product is tracked and detected by an advanced computer detector, and the processing precision of the sphere is high. Since the valve body material is the same as the pipe material, there will be no uneven stress, and no deformation due to earthquakes and vehicles passing the ground. The sealing ring body is made of PTFE material with a content of 20% C (carbon), which guarantees no stress. Leak (0%).

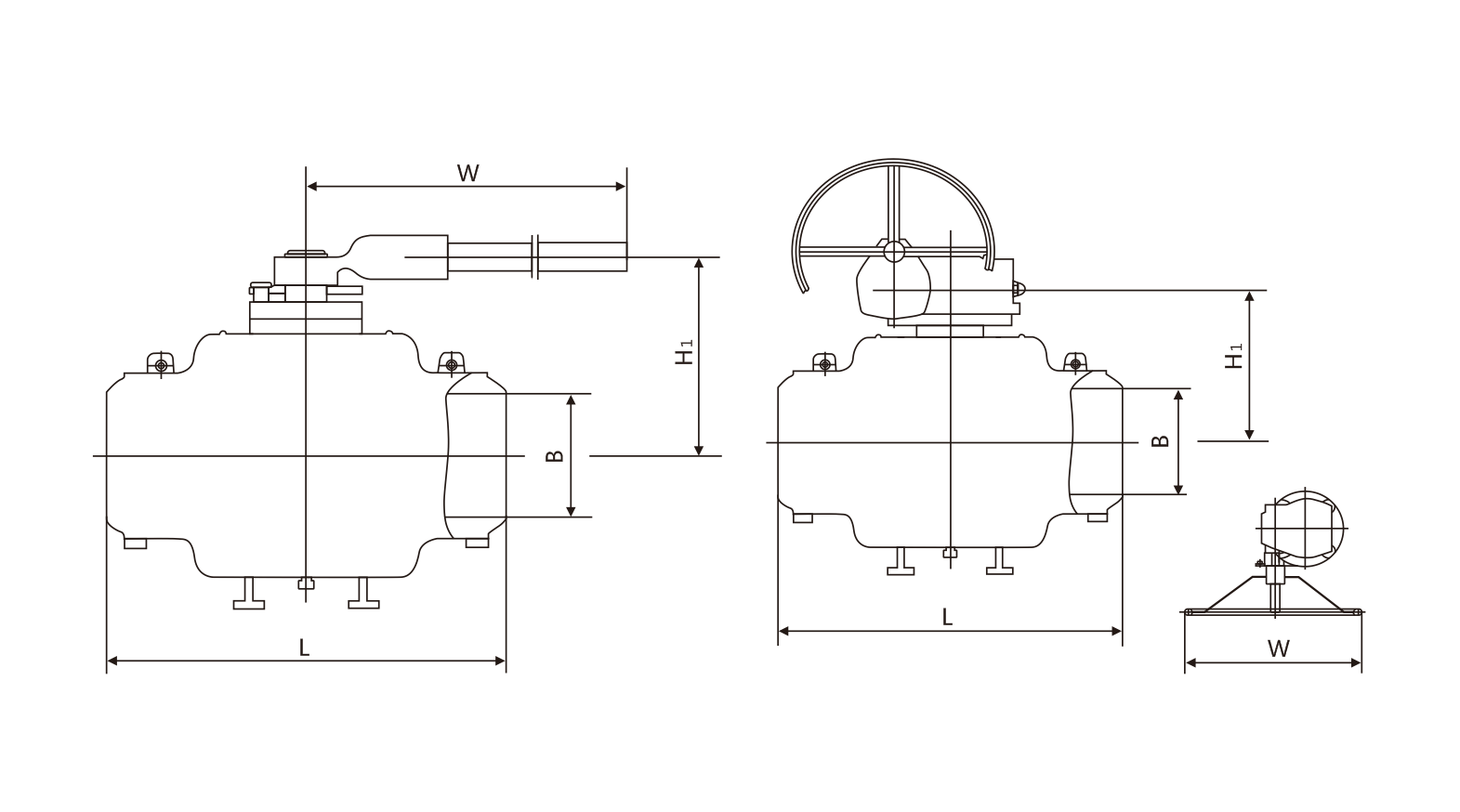

Main external connection size (Class 600)

| NPS(in) | L | H2 | P | B | WT(kg) | T(N.m) |

| 6 | 559 | 290 | 600 | 150 | 232 | 800 |

| 8x6 | 660 | 290 | 600 | 150 | 282 | 800 |

| 8 | 660 | 340 | 600 | 201 | 408 | 1600 |

| 10x8 | 787 | 340 | 600 | 201 | 491 | 1600 |

| 10 | 787 | 380 | 600 | 252 | 650 | 2864 |

| 12x10 | 838 | 380 | 600 | 252 | 816 | 2864 |

| 12 | 8368 | 440 | 700 | 303 | 850 | 4300 |

| 14x12 | 889 | 440 | 700 | 303 | 1150 | 4300 |

| 14 | 889 | 480 | 700 | 334 | 1115 | 5200 |

| 16x12 | 991 | 440 | 700 | 303 | 1450 | 4300 |

| 16x14 | 991 | 480 | 700 | 334 | 1330 | 5200 |

| 16 | 991 | 500 | 762 | 385 | 1550 | 7000 |

| 18x16 | 1092 | 500 | 762 | 385 | 1740 | 7000 |

| 18 | 1092 | 560 | 762 | 436 | 1880 | 10600 |

| 20x18 | 1194 | 560 | 762 | 487 | 1960 | 10600 |

| 20 | 1194 | 620 | 762 | 487 | 2635 | 15000 |

| 24x20 | 1397 | 620 | 762 | 589 | 3250 | 15000 |

| 24 | 1397 | 680 | 762 | 589 | 3660 | 25000 |

| 28x24 | 1549 | 680 | 762 | 589 | 3920 | 25000 |

| 28 | 1549 | 840 | 762 | 684 | 4680 | 32000 |

| 30x28 | 1561 | 840 | 762 | 684 | 5210 | 32000 |

| 32x28 | 1778 | 840 | 762 | 684 | 5686 | 32000 |

Jing12011202000600

Jing12011202000600