Handle fully welded ball valve

Product overview

Valve model: Q61F

Connection method: welding, butt welding

Pressure rating: PN 1.0-4.0MPa

Product specifications: DN10~40mm

Product material: WCB, A105, F11, F22, F304, F316, CF8, CF8M, WCC or according to customer requirements

Applicable temperature: -29℃≤t≤150℃ (the temperature is different from the material of the valve body and the sealing surface)

Applicable media: water, oil, natural gas, acid and alkali media, etc.

Drive mode: handle

Product description

Handle type fully welded ball valves are widely used in various fields. Its superior quality and high-performance stability are beyond the reach of ordinary cast steel ball valves. Its service life is much longer than that of cast steel ball valves. Fully welded ball valves are widely used in urban gas, urban heating, petrochemical, shipbuilding, steel, All kinds of pipeline equipment such as pressure regulating station and power plant. The fully welded ball valve can be directly buried in the ground without building a tall valve well to reduce the project cost. At the same time, it can also avoid personnel injury when operating the valve. The fully welded ball valve can be used reliably for a long time. Compared with products of the same specification in similar industries, the valve body is small and beautiful in appearance.

Scope of application

City gas: gas output pipeline, main line and various branch supply pipelines, etc. Centralized heating: output pipelines, main lines, and branch lines of large-scale heating equipment. Heat exchanger: the pipeline and each circuit are opened and closed. Iron and steel plants: various fluid pipelines, exhaust gas discharge channels, gas and heat supply pipelines, fuel supply pipelines, etc. All kinds of industrial equipment: all kinds of heat treatment pipelines, all kinds of industrial gas and heating pipelines.

Executive standard

Design Code: API 6D, ASME B16.34

Pressure-temperature rating: ASME B16.34, API608

Structure length: ASME B16.10, GB12221

Butt welding end form: ASME B16.25, ASME B31.4/31.8

Inspection and test: API 598, API 6D, GB13927

Fire resistance test: API 607, API 6FA

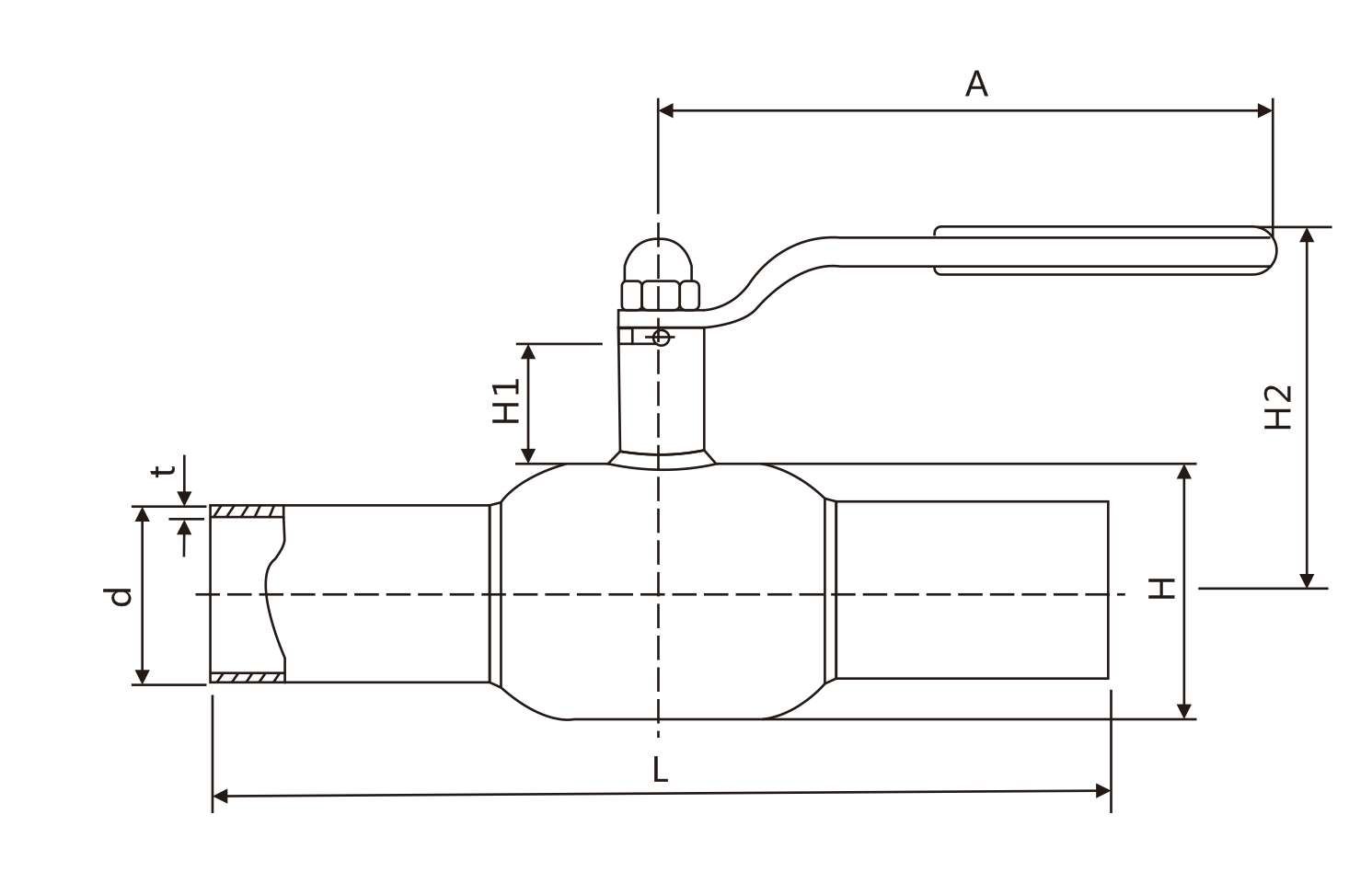

Main external connection size

DN(mm) | Nominal diameter | H | d | t | L | H1 | H2 | A | W T(kg) |

A/B | |||||||||

20 | 15 | 42 | 26.9/25 | 3 | 200 | 47 | 88 | 145 | 1.1 |

25 | 20 | 48 | 33.7/32 | 3 | 230 | 47 | 90 | 145 | 1.4 |

32 | 25 | 60 | 42.4/38 | 3 | 260 | 48 | 95 | 145 | 2 |

40 | 32 | 76 | 48.3/45 | 4 | 260 | 48 | 100 | 180 | 2.7 |

Jing12011202000600

Jing12011202000600