Explosion relief valve

Product overview

Product model: XB-42/61

Nominal diameter: DN300~1000mm

Nominal pressure: 0.1-0.6MPa

Applicable temperature: ≤200℃

Main materials: carbon steel, aluminum alloy

Applicable medium: other explosive gases such as air and coal gas

Installation form: butt welding type, flange type

Flange standard: GB/T9115-98

Connection size: GB2555-81

Testing standard: GB/T13927-92

Product description

The explosion relief valve is composed of valve body, bursting membrane, supporter, valve cover, heavy hammer and other parts. The bursting membrane is installed in the middle of the holder and connected with the valve body by bolts. When the system is overpressured, the rupture film ruptures. The pressure is released instantaneously, and the valve cover will be reset under the action of gravity after popping up. This valve needs to lift up the valve body and holder when replacing the rupture film. The blasting film is prepared by the user according to the process characteristics, and is mainly used in the fields of building materials, metallurgy, petroleum, chemical industry and so on.

Main technical parameters

Nominal diameter | DN(mm) | 300~1000 |

Suitable for blasting calculation pressure (absolute) | PN(MPa) | 0.1 |

Strength test pressure | 1.5 | |

proper temperature | ≤200℃ | |

Applicable medium | Compressed explosive gas | |

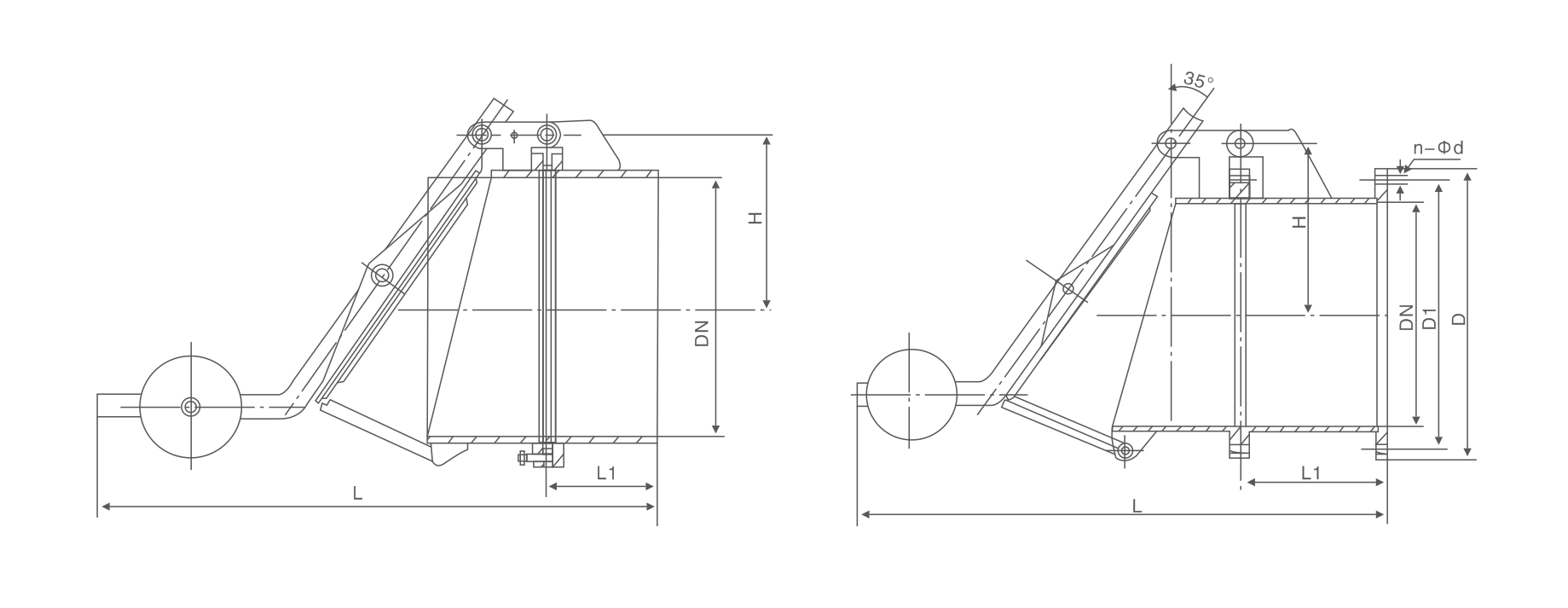

Main shape and connection size

| DN | D | n-φd | D1 | b | L | L1 | H | Weight (kg) |

| 300 | 440 | 12-φ22 | 395 | 16 | 880 | 250 | 250 | 52 |

| 350 | 490 | 12-φ22 | 445 | 16 | 907 | 250 | 275 | 69 |

| 400 | 540 | 16-φ22 | 495 | 16 | 1010 | 250 | 300 | 77 |

| 450 | 595 | 16-φ22 | 550 | 16 | 1060 | 252 | 325 | 83 |

| 500 | 645 | 20-φ22 | 600 | 20 | 1180 | 300 | 370 | 112 |

| 600 | 755 | 20-φ26 | 705 | 20 | 1280 | 300 | 420 | 152 |

| 700 | 860 | 24-φ26 | 810 | 20 | 1390 | 300 | 470 | 193 |

| 800 | 975 | 24-φ30 | 920 | 20 | 1480 | 300 | 520 | 165 |

| 900 | 1075 | 24-φ30 | 1020 | 20 | 1590 | 350 | 600 | 335 |

| 1000 | 1175 | 28-φ30 | 1120 | 20 | 1680 | 350 | 650 | 375 |

Jing12011202000600

Jing12011202000600