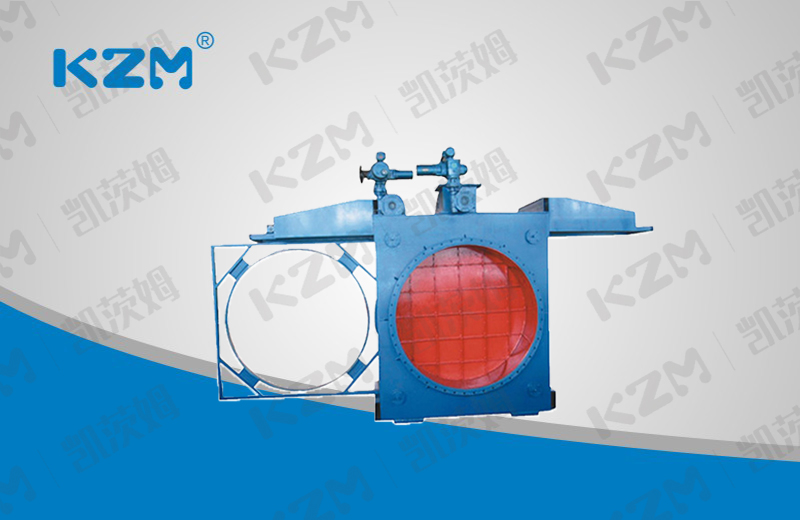

Electric open type flapper valve

Product overview

Product model: KF941X

Nominal diameter: DN400~2800mm

Nominal pressure: 0.05~0.25MPa

Applicable temperature: 200°C (silicone rubber), 300°C (fluorine rubber)

Drive mode: electric, hydraulic, pneumatic, electro-hydraulic

Applicable medium: air, heating furnace gas, blast furnace gas, converter gas, flue gas, etc.

Body material: carbon steel, rubber, chrome steel

Design standards: API 600, API6D, ASME B16.34, GB/T 12234

Structure length: ASME B16.10, API6D, GB/T 12221

Connection standards: ASME B16.5, ASME B16.47, GB/T 9113, JB/T 79, HG/T 20592

Pressure test: API 598, GB/T 13927, JB/T 9092

Pressure-temperature rating: ASME B16.34, GB/T 12224

Structural features and uses

The valve is an open design structure, which is light in weight and easy to maintain (seal rubber ring replacement, electric device maintenance inspection, replacement, and partial valve maintenance are all external, which does not affect the normal operation of the valve). The valve movement process and switch status are intuitive It has good performance, and it is extremely convenient to check the completed state after opening and closing. It has the advantage of being closed and irreplaceable. The disadvantage is that there is a small amount of gas leakage during opening and closing. The compression transmission mechanism adopts ring gear, gear, trapezoidal thread, and screw pair to simultaneously compress in both directions. The advantages of the synchronous compression of the left and right trapezoidal threaded screw rods are: small starting torque, good self-locking of the thread pair, reliable valve sealing, and pin gear transmission mechanism for plate movement, which is not easy to accumulate dust, which meets the need for dust and poor lubrication conditions. Use in harsh working environment.

This valve can be equipped with an explosion-proof control cabinet on the ground to implement on-site control and remote connection control with the PLC system. The design distance is more than 10 meters.

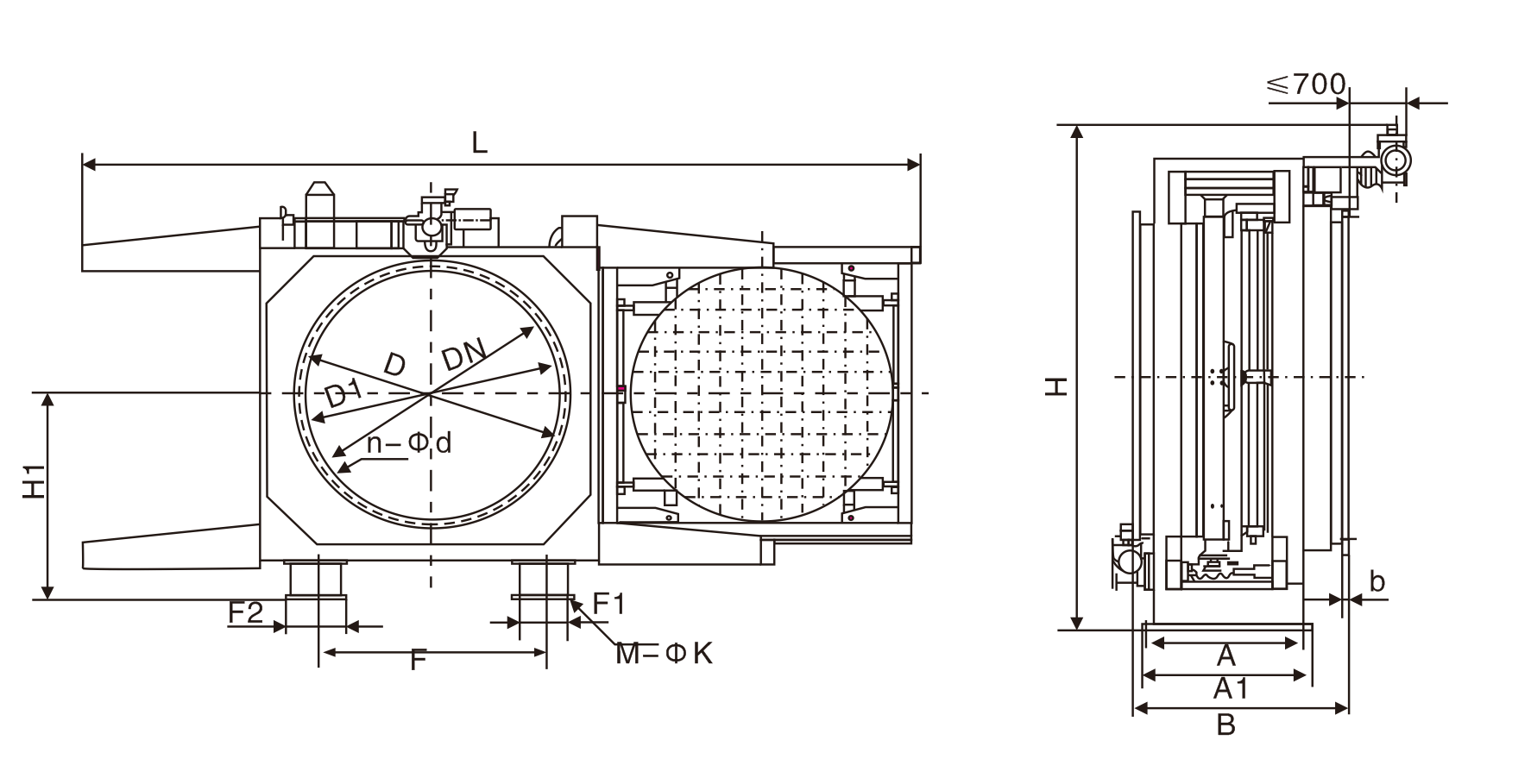

Main dimensions

| DN | D | D1 | B | b | n-d | H | H1 | L | A | A1 | F | F1 | F2 | M-K | Electric power (kw) | Weight (kg) | ||||

| Walking board | Splint | PN0.05 | PN0.10 | PN0.15 | PN0.25 | |||||||||||||||

| 400 | 540 | 495 | 600 | 18 | 16-22 | 1300 | 350 | 2210 | 600 | 680 | 500 | 160 | 220 | 4-23 | 1.1 | 1.5 | 880 | 960 | ||

| 450 | 595 | 550 | 600 | 18 | 16-22 | 1520 | 400 | 2400 | 600 | 680 | 500 | 160 | 220 | 4-23 | 1.1 | 1.5 | 980 | 1060 | ||

| 500 | 645 | 600 | 600 | 18 | 20-26 | 1600 | 450 | 2540 | 600 | 680 | 500 | 160 | 220 | 4-23 | 1.1 | 1.5 | 1050 | 1180 | ||

| 600 | 755 | 705 | 800 | 24 | 24-26 | 1750 | 500 | 2720 | 600 | 680 | 900 | 280 | 340 | 8-23 | 1.1 | 1.5 | 1150 | 1280 | ||

| 700 | 860 | 810 | 800 | 24 | 24-30 | 1884 | 720 | 2815 | 600 | 680 | 950 | 280 | 340 | 8-23 | 1.1 | 1.5 | 1210 | 1320 | ||

| 800 | 975 | 920 | 800 | 24 | 24-30 | 1970 | 800 | 3115 | 600 | 680 | 1045 | 280 | 340 | 8-23 | 1.5 | 1.5 | 1450 | 1600 | ||

| 900 | 1075 | 1020 | 800 | 24 | 24-30 | 2086 | 880 | 3640 | 600 | 680 | 1250 | 280 | 340 | 8-23 | 2.2 | 2.2 | 1840 | 2050 | ||

| 1000 | 1175 | 1120 | 800 | 24 | 28-30 | 2250 | 960 | 3940 | 820 | 910 | 1250 | 280 | 340 | 8-23 | 2.2 | 2.2 | 2180 | 2450 | ||

| 1200 | 1375 | 1320 | 1200 | 26 | 32-30 | 2837 | 1165 | 5930 | 1100 | 1180 | 1060 | 480 | 560 | 8-33 | 1.1 | 2.2 | 2600 | 2800 | ||

| 1400 | 1575 | 1520 | 1200 | 26 | 36-30 | 3057 | 1285 | 6530 | 1100 | 1220 | 1400 | 480 | 560 | 8-33 | 1.1 | 1.5 | 3250 | 3550 | ||

| 1600 | 1790 | 1730 | 1200 | 32 | 40-30 | 3257 | 1385 | 7130 | 1100 | 1180 | 1560 | 480 | 560 | 8-33 | 1.5 | 1.5 | 4350 | 4750 | ||

| 1800 | 1990 | 1930 | 1400 | 32 | 44-30 | 3400 | 1428 | 7730 | 1100 | 1180 | 1750 | 230 | 560 | 8-33 | 2.2 | 2.2 | 5100 | 5600 | ||

| 2000 | 2190 | 2130 | 1400 | 32 | 48-30 | 4010 | 1850 | 8400 | 1200 | 1280 | 1800 | 230 | 560 | 8-33 | 2.2 | 2.2 | 5760 | 6250 | ||

| 2200 | 2405 | 2340 | 1600 | 32 | 52-30 | 4110 | 1950 | 9050 | 1200 | 1280 | 1900 | 230 | 560 | 8-33 | 2.2 | 2.2 | 7050 | 7750 | ||

| 2400 | 2605 | 2540 | 1600 | 32 | 56-33 | 4365 | 2050 | 9600 | 1200 | 1280 | 2360 | 230 | 560 | 8-33 | 2.2 | 2.2 | 8250 | 9050 | ||

| 2600 | 2805 | 2740 | 1800 | 34 | 60-33 | 4375 | 2141 | 8567 | 1340 | 1410 | 2332 | 300 | 600 | 8-36 | 2.2 | 2.2 | 9700 | 10500 | ||

| 2800 | 2960 | 3030 | 1800 | 36 | 64-36 | 4554 | 2280 | 8925 | 1340 | 1410 | 2532 | 300 | 600 | 8-36 | 2.2 | 2.2 | 12000 | 13200 | ||

Jing12011202000600

Jing12011202000600