Product description

Impeller feeder, also called star unloader, is the main equipment for conveying, ash discharge, air lock and other equipment feeding of dust removal equipment. It is used to continuously and evenly feed the dry powdery materials or small particles in the upper silo to the next equipment. This feeder is widely used in material conveying systems of cement, building materials, chemical industry, metallurgy and light industry as feeding equipment. Impeller feeder is a kind of quantitative feeding equipment, this machine is equipped with BLY series cycloidal pinwheel reducer, which is directly rigidly connected with the main shaft through the output shaft of the reducer, thereby driving the main shaft and the impeller to rotate. A number of impeller blades are installed on the impeller, and a rubber sealing sheet is installed on the impeller, which is pressed tightly with a pressure plate, and the seal sheet is tightly attached to the inner wall of the shell. When the motor rotates, the main shaft and the impeller rotate at the same time. When the material passes through the upper silo, the material port enters the impeller groove, and the rotating impeller takes the material to the discharge port and feeds it out.

Features

1. The unloader adopts the principle of planetary rotation, the input and output are on the same axis, and it has the uniqueness of being directly connected to the motor, so it has a compact structure, beautiful appearance, small size, and light weight.

2. The unloader runs reliably and smoothly, with low noise, fewer failures, and long life. The teeth are made of nodular cast iron and bearing steel. Good performance and high wear resistance

3. Bearings, gear boxes, keep away from the valve body, avoid the influence of high temperature and dust, the front and rear covers have good sealing performance, prevent dust from leaking, and extend the service life of motor parts and lubrication systems.

4. The impeller feeder has strong overload capacity, small impact resistance and small moment of inertia, and is suitable for frequent starting and reverse rotation.

5. If users need special specifications, unloaders such as motors, sprocket drives, etc. can be manufactured.

Main technical parameters

| Model specification | Production capacity (M3/hour) | Impeller speed (Rev/min) | Import and export size Length×width(mm) | transfer method | Cycloidal pinwheel reduction motor | Overall dimensions of feeder body Length × width × height (mm) | Feeder body weight (Kg) | ||

| model | Work rate | Rotating speed | |||||||

| GY-Φ200×200 | 7 | 34 | 200×200 | Cycloid reducer | BLY18-43 | 1.1 | 34 | 510×300×300 | 67 |

| GY-Φ200×300 | 10 | 34 | 200×300 | BLY18-43 | 1.1 | 34 | 610×300×300 | 77 | |

| GY-Φ300×300 | 23 | 34 | 300×300 | BLY18-43 | 1.1 | 34 | 690×400×450 | 155 | |

| GY-Φ300×400 | 31 | 34 | 300×400 | BLY18-43 | 1.5 | 34 | 790×400×450 | 174 | |

| GY-Φ400×400 | 53 | 34 | 400×400 | BLY22-43 | 3 | 34 | 830×520×600 | 231 | |

| GY-Φ400×500 | 67 | 34 | 400×500 | BLY22-43 | 3 | 34 | 960×520×600 | 268 | |

| GY-Φ500×500 | 106 | 34 | 500×500 | BLY22-43 | 4 | 34 | 960×640×760 | 550 | |

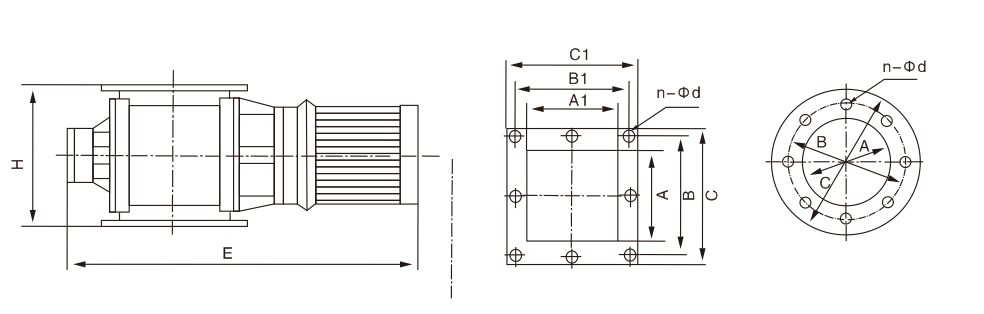

Main dimensions (GYT/W-4)

| A(A1) | B(B1) | C(C1) | n-φd | H | M | F | E | GYW-4 weight | GYW-4Z weight | GYW-4J weight |

| φ150 | φ240 | φ210 | 8-φ11 | 230 | 720 | 600 | 520 | 40 | 250 | 270 |

| φ200 | φ300 | φ260 | 8-φ11 | 300 | 800 | 700 | 570 | 75 | 275 | 295 |

| φ250 | φ350 | φ310 | 8-φ13 | 340 | 850 | 750 | 660 | 100 | 320 | 340 |

| φ300 | φ400 | φ360 | 8-φ17 | 400 | 900 | 800 | 730 | 155 | 380 | 400 |

| φ350 | φ450 | φ410 | 8-φ17 | 450 | 960 | 860 | 780 | 190 | 500 | 520 |

| φ400 | φ500 | φ460 | 8-φ17 | 500 | 1020 | 920 | 820 | 240 | 700 | 720 |

| φ450 | φ600 | φ560 | 8-φ17 | 600 | 1080 | 980 | 940 | 280 | 900 | 930 |

| φ500 | φ710 | φ660 | 8-φ17 | 700 | 1140 | 1040 | 990 | 320 | 1100 | 1150 |

| 150×150 | 240×240 | 210×210 | 8-φ11 | 230 | 720 | 600 | 520 | 45 | 260 | 280 |

| 150×200 | 240×300 | 210×260 | 8-φ11 | 230 | 800 | 700 | 570 | 60 | 290 | 310 |

| 200×200 | 300×300 | 260×260 | 8-φ11 | 300 | 800 | 700 | 570 | 80 | 310 | 330 |

| 200×300 | 300×400 | 260×360 | 8-φ13 | 300 | 900 | 800 | 730 | 140 | 330 | 350 |

| 300×300 | 400×400 | 360×360 | 8-φ17 | 400 | 960 | 860 | 730 | 160 | 390 | 410 |

| 300×400 | 400×500 | 360×460 | 16-φ17 | 400 | 1020 | 920 | 820 | 220 | 510 | 530 |

| 400×400 | 500×500 | 460×460 | 16-φ17 | 500 | 1020 | 920 | 820 | 250 | 560 | 590 |

| 400×500 | 500×710 | 460×660 | 16-φ17 | 600 | 1140 | 1040 | 990 | 300 | 980 | 1020 |

| 500×500 | 710×710 | 660×660 | 16-φ17 | 700 | 1140 | 1040 | 990 | 350 | 1150 | 1200 |

Outline and connection size (YJD-A/B)

| Liter per revolution | A | B | C | A1 | B1 | C1 | H | M | F | E | Hole diameter | Weight kg |

| 2 | 150 | 200 | 240 | 150×150 | 200×200 | 240×240 | 240 | 120 | 120 | ~500 | 8-9-21 | 40 |

| 4 | 180 | 240 | 280 | 180×180 | 230×230 | 260×260 | 280 | 140 | 140 | ~530 | 8-11-21 | 60 |

| 6 | 200 | 260 | 300 | 200×200 | 250×250 | 280×280 | 300 | 150 | 150 | ~550 | 8-11-21 | 75 |

| 8 | 220 | 280 | 320 | 220×220 | 270×270 | 300×300 | 320 | 160 | 160 | ~580 | 8-11-21 | 80 |

| 10 | 240 | 300 | 340 | 240×240 | 290×290 | 320×320 | 340 | 170 | 170 | ~600 | 8-13-21 | 100 |

| 12 | 260 | 320 | 360 | 260×260 | 310×310 | 340×340 | 360 | 180 | 180 | ~620 | 8-13-21 | 115 |

| 14 | 280 | 340 | 380 | 280×280 | 330×330 | 360×360 | 380 | 190 | 190 | ~640 | 8-17-21 | 130 |

| 16 | 300 | 360 | 400 | 300×300 | 350×350 | 380×380 | 400 | 200 | 200 | ~670 | 8-17-21 | 150 |

| 18 | 320 | 380 | 420 | 320×320 | 370×370 | 400×400 | 420 | 210 | 210 | ~690 | 8-17-21 | 165 |

| 20 | 340 | 400 | 440 | 340×340 | 390×390 | 420×420 | 440 | 220 | 220 | ~710 | 8-17-21 | 190 |

| 26 | 400 | 460 | 500 | 400×400 | 450×450 | 480×480 | 500 | 250 | 250 | ~770 | 8-17-21 | 230 |

| 30 | 440 | 500 | 540 | 440×440 | 490×490 | 520×520 | 540 | 270 | 270 | ~820 | 8-17-21 | 280 |

| 36 | 500 | 560 | 600 | 500×500 | 550×550 | 580×580 | 600 | 300 | 300 | ~950 | 8-20-21 | 320 |

| 40 | 540 | 600 | 640 | 540×540 | 590×590 | 620×620 | 640 | 320 | 320 | ~990 | 8-20-21 | 400 |

Jing12011202000600

Jing12011202000600