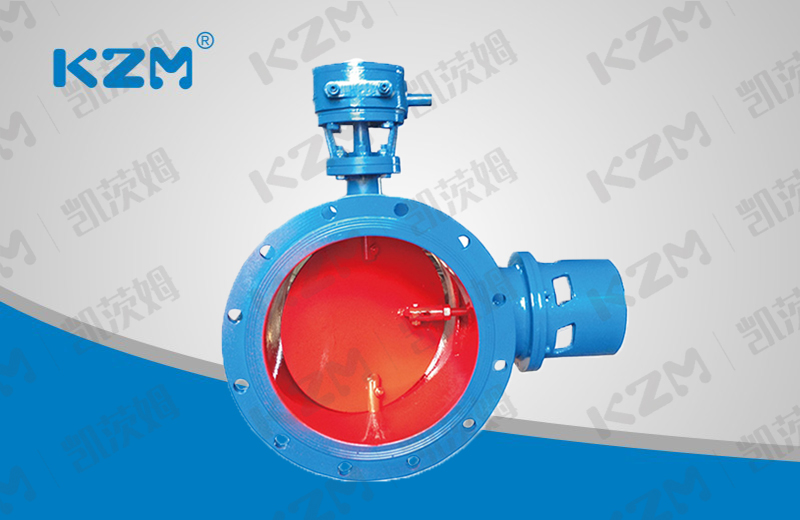

Hand (electric) moving butterfly type cold air relief valve

Product overview

Product model: FS48(948)W

Nominal diameter: DN400~2800mm

Nominal pressure: 0.05~0.25MPa

Applicable temperature: ≤250℃

Drive mode: electric, hydraulic, pneumatic, electro-hydraulic

Applicable medium: air, heating furnace gas, blast furnace gas, converter gas, flue gas, etc.

Body material: carbon steel, rubber, chrome steel

Design standards: API 600, API6D, ASME B16.34, GB/T 12234

Structure length: ASME B16.10, API6D, GB/T 12221

Connection standards: ASME B16.5, ASME B16.47, GB/T 9113, JB/T 79, HG/T 20592

Pressure test: API 598, GB/T 13927, JB/T 9092

Pressure-temperature rating: ASME B16.34, GB/T 12224

Product description

The hand (electric) butterfly type cold air release valve is composed of valve body, butterfly plate, connecting rod, muffler, exhaust duct and other parts. Use a manual lever mechanism or an electric device to turn the butterfly plate to open and close the valve, so as to reduce or completely stop the air supply to the blast furnace without stopping the blower, and exhaust the excess gas to the atmosphere. The special place in its structure is an electric drive that can be operated remotely. By moving the size of the air release valve disc, the air volume can be easily changed, and the signal is output through the automatic position reversal on the air release valve. Use the DFP-09 electric operator to display the size of the valve opening. As long as the electric operator is controlled, the required air volume can be achieved. It is suitable for the ventilation pipes of building materials, metallurgy, chemical industry, power stations and other industries, as a device for automatically adjusting or remotely controlling the air volume required by the equipment. Under given wind pressure conditions, the required air volume is automatically controlled by servo amplifier, electric operator, valve position feedback and other devices. The structure is simple and the operation is convenient; in order to have a good valve opening linearity, a double valve flap structure is adopted.

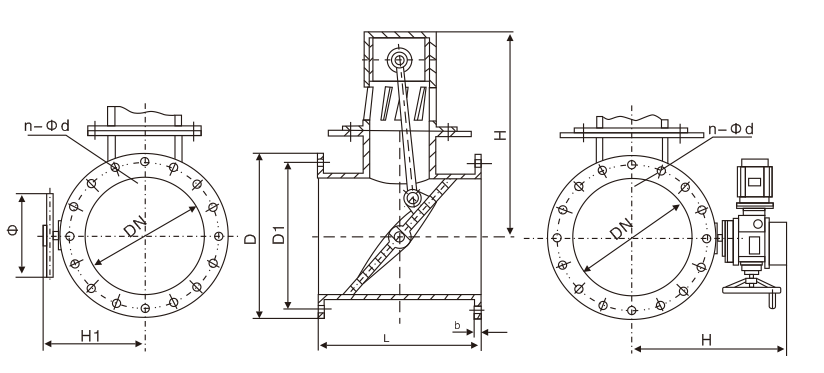

Main shape and connection size

DN | D1 | D | L | b | N-d | H | H1 | H2 | & | Weight (Kg) | |

Manual | electric | ||||||||||

400 | 495 | 540 | 350 | 16 | 16-22 | 650 | 380 | 660 | 350 | 205 | 225 |

450 | 550 | 595 | 370 | 16 | 16-22 | 700 | 380 | 690 | 350 | 228 | 250 |

500 | 600 | 645 | 400 | 20 | 20-22 | 730 | 450 | 720 | 400 | 265 | 300 |

600 | 705 | 755 | 530 | 20 | 20-26 | 870 | 525 | 780 | 400 | 403 | 440 |

700 | 810 | 860 | 60 | 24 | 24-26 | 1070 | 600 | 830 | 500 | 650 | 685 |

800 | 920 | 975 | 750 | 24 | 24-30 | 1190 | 700 | 880 | 500 | 850 | 890 |

900 | 1020 | 1075 | 750 | 24 | 24-30 | 1510 | 750 | 930 | 600 | 1100 | 1140 |

1000 | 1120 | 1175 | 800 | 28 | 28-30 | 1680 | 800 | 1000 | 600 | 1380 | 1430 |

1200 | 1320 | 1375 | 900 | 32 | 32-30 | 1880 | 900 | 1100 | 700 | 1880 | 1930 |

1400 | 1520 | 1575 | 1000 | 36 | 36-30 | 2110 | 1050 | 1250 | 700 | 2530 | 2590 |

Jing12011202000600

Jing12011202000600