Hydraulic sector blind valve

Product overview

Product model: F743X

Nominal diameter: DN300~2000mm

Nominal pressure: PN0.05~0.25MPa

Applicable temperature: ≤300℃

Applicable medium: coal gas and toxic, harmful, flammable gas

Main materials: carbon steel, stainless steel, silicon rubber

Drive mode: electric, hydraulic, pneumatic, electro-hydraulic

Design standards: API 600, API6D, ASME B16.34, GB/T 12234

Structure length: ASME B16.10, API6D, GB/T 12221

Connection standards: ASME B16.5, ASME B16.47, GB/T 9113, JB/T 79, HG/T 20592

Pressure test: API 598, GB/T 13927, JB/T 9092

Pressure-temperature rating: ASME B16.34, GB/T 12224

Product description

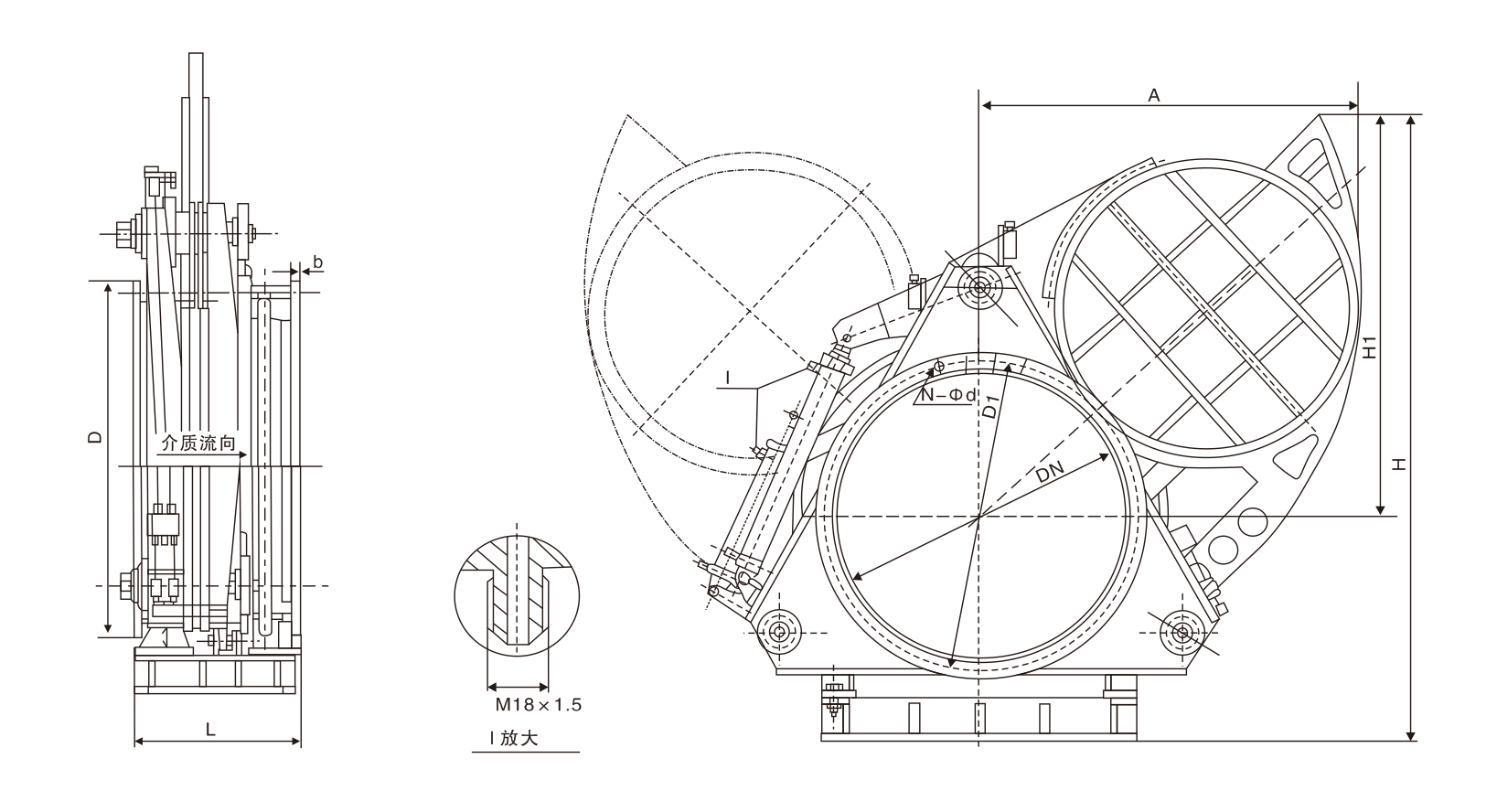

The hydraulic fan-shaped blind plate valve is mainly composed of left valve body, right valve body, screw pair, flap, sealing ring, lever, hydraulic cylinder and other parts, and a rigid structure is formed by a base and a supporting column. The valve is equipped with a clamping oil cylinder and a flap oil cylinder. The clamping oil cylinder drives the left and right valve bodies through a lever pair and a screw screw pair to complete the loosening and clamping action, and the flap oil cylinder drives the valve plate to complete the switching action. The rubber sealing ring is embedded in the valve plate, which has the characteristics of high temperature resistance, good sealing performance, easy replacement and long service life.

This valve can be controlled remotely by a single unit or by multiple units connected to the network. Under abnormal conditions, the valve itself can also be operated manually.

Main connection dimensions

| DN | L | D | D1 | A | H | H1 | b | n-Φd | Weight (kg) | ||

| PN0.05 | PN0.15 | PN0.25 | |||||||||

| 300 | 450 | 440 | 395 | 480 | 720 | 360 | 22 | 12-22 | 205 | 225 | 250 |

| 350 | 450 | 490 | 445 | 520 | 810 | 380 | 22 | 12-22 | 235 | 255 | 280 |

| 400 | 450 | 540 | 495 | 600 | 920 | 400 | 22 | 16-22 | 250 | 275 | 300 |

| 450 | 500 | 595 | 550 | 658 | 995 | 427 | 24 | 16-22 | 300 | 330 | 360 |

| 500 | 500 | 645 | 600 | 712 | 1102 | 452 | 24 | 20-22 | 350 | 385 | 420 |

| 600 | 600 | 755 | 705 | 874 | 1600 | 650 | 26 | 20-26 | 420 | 460 | 500 |

| 700 | 600 | 860 | 810 | 970 | 1700 | 700 | 30 | 24-26 | 560 | 610 | 670 |

| 800 | 800 | 975 | 920 | 1100 | 1860 | 1125 | 30 | 24-30 | 1500 | 1650 | 1750 |

| 900 | 800 | 1075 | 1020 | 1200 | 2055 | 1270 | 32 | 24-30 | 1800 | 1950 | 2050 |

| 1000 | 800 | 1175 | 1120 | 1320 | 2240 | 1400 | 35 | 28-30 | 2100 | 2310 | 2500 |

| 1100 | 800 | 1275 | 1220 | 1510 | 2425 | 1535 | 35 | 28-30 | 2300 | 2500 | 2750 |

| 1200 | 800 | 1375 | 1320 | 1625 | 2621 | 1680 | 35 | 32-30 | 2600 | 2850 | 3200 |

| 1300 | 800 | 1475 | 1420 | 1749 | 2760 | 1770 | 35 | 32-33 | 3000 | 3300 | 3600 |

| 1400 | 850 | 1575 | 1520 | 1856 | 2960 | 1925 | 35 | 36-30 | 4170 | 4520 | 4900 |

| 1500 | 850 | 1690 | 1630 | 1976 | 3105 | 2050 | 35 | 36-30 | 4400 | 5150 | 5650 |

| 1600 | 850 | 1790 | 1730 | 1293 | 3300 | 2160 | 35 | 40-30 | 4750 | 5650 | 6150 |

| 1800 | 1100 | 1990 | 1930 | 2335 | 3610 | 2370 | 35 | 44-30 | 5750 | 7350 | 8050 |

| 2000 | 1100 | 2190 | 2130 | 2570 | 3960 | 2620 | 35 | 46-30 | 6750 | 9350 | 9800 |

Jing12011202000600

Jing12011202000600