Pneumatic sector blind valve

Product overview

Product model: F643X

Nominal diameter: DN300~1600mm

Nominal pressure: PN0.05~0.25MPa

Applicable temperature: ≤450℃

Applicable medium: coal gas and toxic, harmful, flammable gas

Main materials: carbon steel, stainless steel, silicon rubber

Drive mode: electric, hydraulic, pneumatic, electro-hydraulic

Design standards: API 600, API6D, ASME B16.34, GB/T 12234

Structure length: ASME B16.10, API6D, GB/T 12221

Connection standards: ASME B16.5, ASME B16.47, GB/T 9113, JB/T 79, HG/T 20592

Pressure test: API 598, GB/T 13927, JB/T 9092

Pressure-temperature rating: ASME B16.34, GB/T 12224

Product description

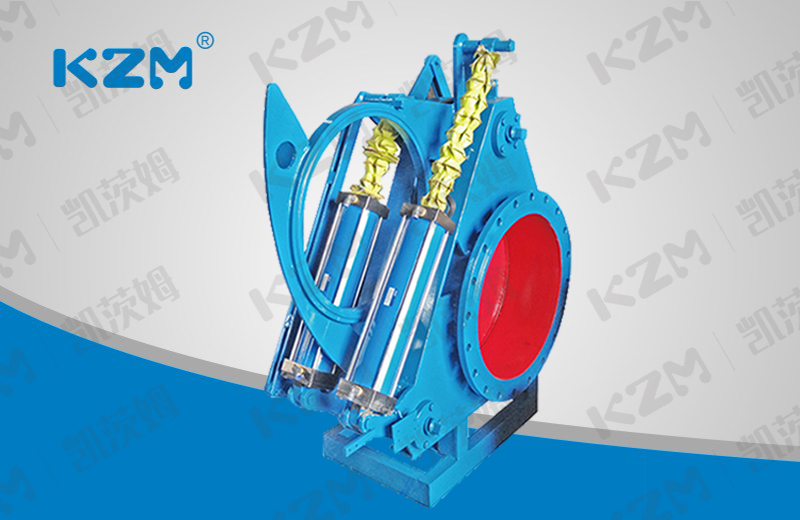

The pneumatic sector blind valve is mainly composed of left valve body, right valve body, valve stem, gate, sealing ring, pneumatic push rod and other parts, and a rigid structure is formed by a base and a supporting column. The sealing part adopts stainless steel and rubber sealing ring, which has good sealing performance and long service life. The sealing ring is set on the gate, and it is easy to replace the sealing ring during maintenance. The rubber sealing ring is inlaid on the gate. The pneumatic push rod blind plate valve can be controlled by a single unit, or multiple units can be networked for remote control. Under abnormal conditions, it can also be operated manually by the valve itself. It is widely used in coal gas and toxic gas medium pipelines in industrial and mining enterprises, environmental protection and other industries, as a reliable cutting device.

Structural features

1. This valve is composed of left and right valve bodies, fan-shaped valve plates, stainless steel bellows, driving devices, clamping devices and other components;

2. The valve body adopts a three-point locking fan-shaped valve plate structure;

3. The sealing part adopts stainless steel and rubber sealing ring, which has reliable sealing performance, thereby increasing the service life of the sealing ring. The sealing ring is arranged on the valve plate to facilitate the replacement of the sealing ring during maintenance;

4. Actuator operation, stable work, flexible opening and closing, reliable action;

5. The clamping action adopts screw nut pair for clamping, which has good self-locking performance;

6. The blind plate valve is equipped with stainless steel bellows, which has the advantages of strong flexibility and long service life.

Working principle

1. The valve changes from opening to closing:

Clamp the motor to drive the screw rod to rotate counterclockwise, the valve body is loosened in place (the indicator light shows), the motor is driven to drive the gate to rotate counterclockwise in place, the gate is closed in place (displayed by the indicator light), and the motor is clamped The action drives the screw rod to rotate clockwise, and the valve body is clamped in place (displayed by the indicator light) to complete the whole process of the valve from opening to closing.

2. The valve changes from closed to open:

Clamp the motor, drive the screw to rotate counterclockwise, loosen the valve body (indicator light display), drive the motor, drive the gate to rotate clockwise, the gate is opened in place, (displayed by the indicator light), the valve is closed To the whole process of opening.

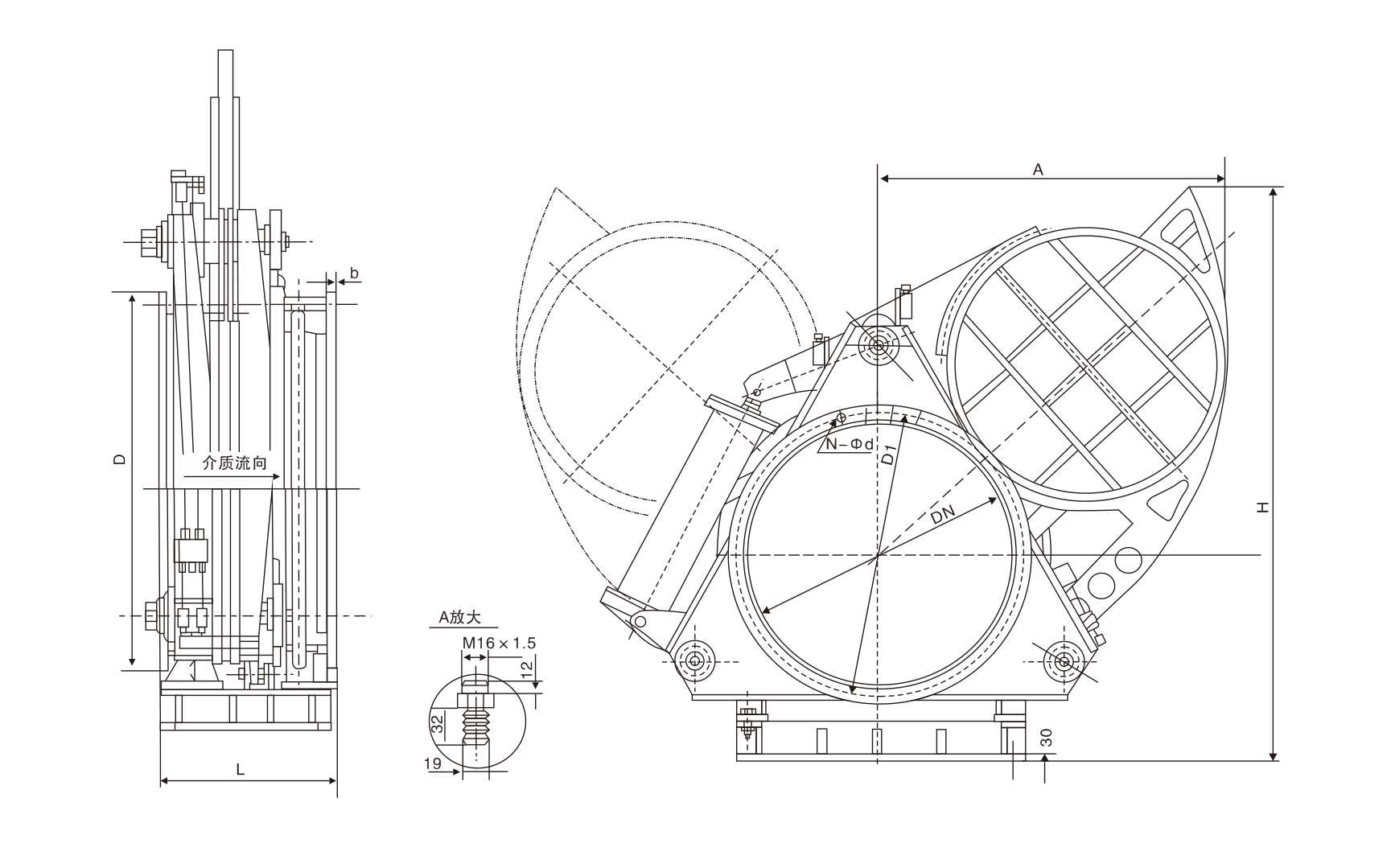

Main external connection size

| DN | L | D | D1 | A | H | b | n-Φd | Weight kg | |||

| PN0.05 | PN0.10 | PN0.15 | PN0.25 | ||||||||

| 300 | 450 | 440 | 395 | 480 | 720 | 16 | 12-φ22 | 255 | 280 | ||

| 350 | 450 | 490 | 445 | 520 | 810 | 16 | 12-φ22 | 285 | 310 | ||

| 400 | 450 | 540 | 495 | 600 | 920 | 16 | 16-φ22 | 300 | 330 | ||

| 450 | 500 | 595 | 550 | 658 | 995 | 16 | 16-φ22 | 350 | 380 | ||

| 500 | 500 | 645 | 600 | 712 | 1102 | 20 | 20-φ22 | 400 | 440 | ||

| 600 | 600 | 755 | 705 | 920 | 1500 | 20 | 20-φ26 | 500 | 550 | ||

| 700 | 600 | 860 | 810 | 970 | 1600 | 20 | 24-φ26 | 580 | 630 | ||

| 800 | 800 | 975 | 920 | 1100 | 1850 | 35 | 24-φ30 | 1500 | 1650 | ||

| 900 | 800 | 1075 | 1020 | 1200 | 1980 | 35 | 24-φ30 | 1800 | 1980 | ||

| 1000 | 800 | 1175 | 1120 | 1320 | 2200 | 35 | 28-φ30 | 2100 | 2300 | ||

Jing12011202000600

Jing12011202000600