Ammonia Globe Valve

Product overview

Product model: J41B

Nominal diameter: DN10~150mm

Nominal pressure: PN1.6-16.0MPa

Applicable temperature: ≤550℃

Main material: 25, WCB, chromium-nickel alloy, chromium-nickel-molybdenum steel, chromium-molybdenum steel

Applicable medium: water, oil, steam, nitric acid, acetic acid, etc.

Design and manufacture: GB/T12235

Structure length: GB/T12221

Connecting flange: JB/T79.2

Pressure temperature: JB/T74

Test: JB/T9092

Product description

The ammonia stop valve is a special valve for non-corrosive gas ammonia and liquid ammonia. The liquid ammonia stop valve is specially designed for ammonia and fuel gas pipelines or devices. Attention has been paid to fire protection requirements on the structure. The packing is made of polytetrafluoroethylene, and the sealing surface of the ammonia gas stop valve is Babbitt alloy seal, the seal is reliable, and the concealed bar design is absolutely no leakage. The sealing material adopts PTFE or nylon to the body material of the valve body, which is a soft seal. It is suitable for ammonia gas and liquefied petroleum gas pipeline system, as an opening and closing device, and also suitable for other pipelines whose temperature is ≤80℃.

Structural features

1. The product structure is reasonable, the sealing is reliable, the performance is excellent, and the appearance is beautiful.

2. The sealing surface is welded with Co-based cemented carbide, which has good wear resistance, corrosion resistance, scratch resistance and long service life.

3. After quenching and tempering and surface nitriding treatment, the valve stem has good corrosion resistance and scratch resistance.

4. The valve is equipped with an inverted sealing structure, and the sealing is reliable.

5. The material and flange size of the parts can be reasonably selected according to actual working conditions or user requirements to meet various engineering needs.

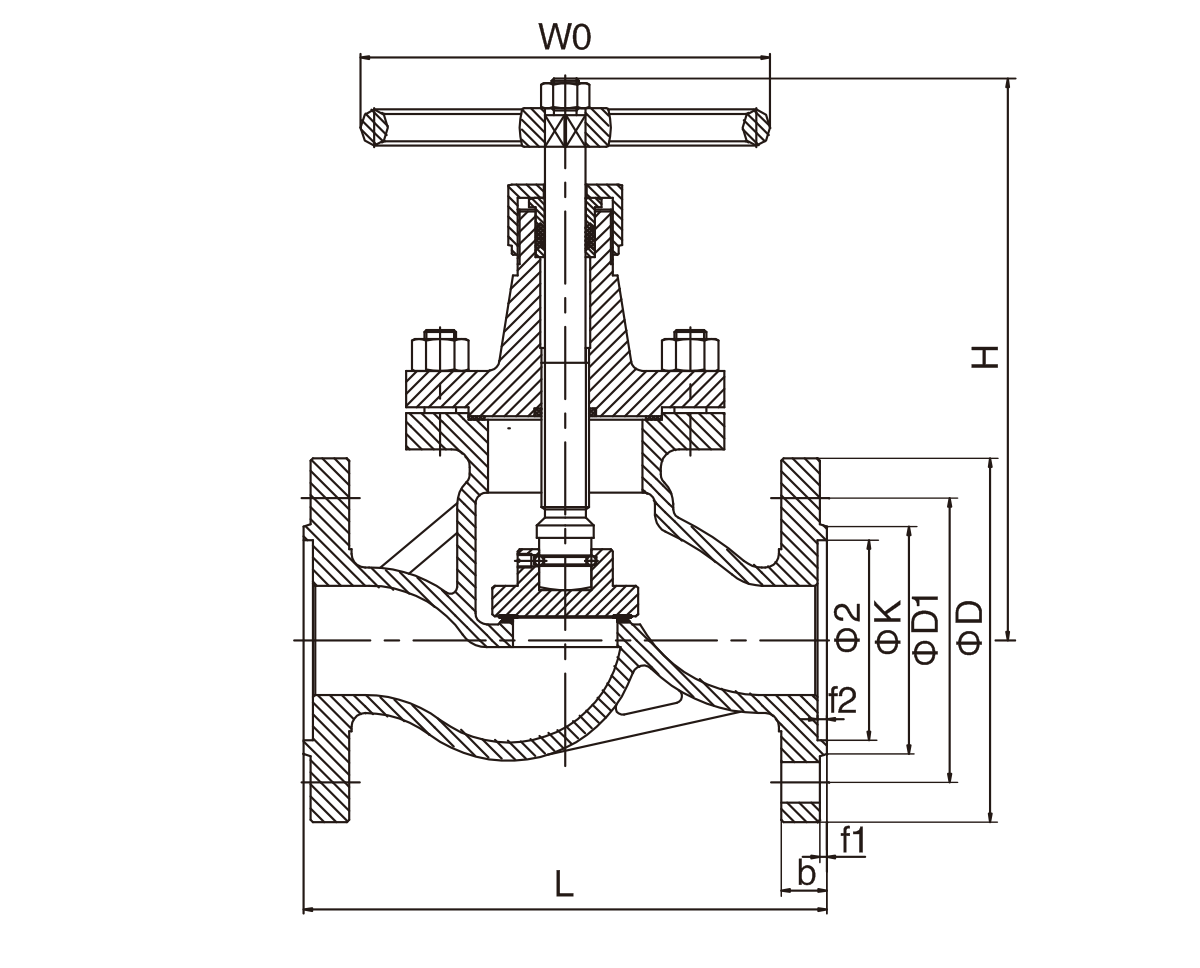

Main external connection size

| DN(mm) | L | D | D1 | K | D2 | b | f1 | f2 | Z-d | H | W0 | ||

| J41B-25C、J41B-25Q、J41B-25K | |||||||||||||

| 10 | 130 | 90 | 60 | 40 | 35 | 16 | 2 | 4 | 4-14 | 196 | 120 | ||

| 15 | 130 | 95 | 65 | 45 | 40 | 16 | 2 | 4 | 4-14 | 196 | 120 | ||

| 20 | 150 | 105 | 75 | 58 | 51 | 18 | 2 | 4 | 4-14 | 196 | 120 | ||

| 25 | 160 | 115 | 85 | 68 | 58 | 18 | 2 | d | 4-14 | 201 | 120 | ||

| 32 | 180 | 140 | 100 | 78 | 66 | 18 | 2 | 4 | 4-18 | 208 | 120 | ||

| 40 | 200 | 150 | 110 | 88 | 76 | 18 | 3 | d | 4-18 | 248 | 160 | ||

| 50 | 230 | 165 | 125 | 102 | 88 | 20 | 3 | 4 | 4-18 | 248 | 160 | ||

| 65 | 290 | 185 | 145 | 122 | 110 | 22 | 3 | 4 | 8-18 | 321 | 240 | ||

| 80 | 310 | 200 | 160 | 138 | 121 | 24 | 3 | 4 | 8-18 | 325 | 240 | ||

| 100 | 350 | 235 | 190 | 162 | 150 | 24 | 3 | 4.5 | 8-22 | 371 | 280 | ||

| 125 | 400 | 270 | 220 | 188 | 176 | 26 | 3 | 4.5 | 8-26 | 400 | 320 | ||

| 150 | 480 | 300 | 250 | 218 | 204 | 28 | 3 | 4.5 | 8-26 | 432 | 320 | ||

| DN(mm) | L | D | D1 | K | D2 | b | f1 | f2 | Z-d | H | W0 | ||

| J41B-40C、J41B-40Q、J41B-40K | |||||||||||||

| 15 | 130 | 95 | 65 | 45 | 40 | 16 | 2 | 4 | 4-14 | 165 | 110 | ||

| 20 | 150 | 105 | 75 | 58 | 51 | 18 | 2 | 4 | 4-14 | 170 | 120 | ||

| 25 | 160 | 115 | 85 | 68 | 58 | 18 | 2 | 4 | 4-14 | 195 | 120 | ||

| 32 | 180 | 140 | 100 | 78 | 66 | 18 | 2 | 4 | 4-18 | 200 | 140 | ||

| 40 | 200 | 150 | 110 | 88 | 76 | 18 | 3 | 4 | 4-18 | 247 | 160 | ||

| 50 | 230 | 165 | 125 | 102 | 88 | 20 | 3 | 4 | 4-18 | 265 | 180 | ||

| 65 | 290 | 185 | 145 | 122 | 110 | 22 | 3 | 4 | 8-18 | 310 | 220 | ||

| 80 | 310 | 200 | 160 | 138 | 121 | 24 | 3 | 4 | 8-18 | 340 | 240 | ||

| 100 | 350 | 235 | 190 | 162 | 150 | 24 | 3 | 4.5 | 8-22 | 380 | 280 | ||

Jing12011202000600

Jing12011202000600