Electric flat gate valve with guide hole

Product overview

General model: DPZ943F

Nominal diameter: DN50-DN1000mm

Nominal pressure: 1.6MPa-10.0MPa

Applicable temperature: - 20 ℃ - 120 ℃

Valve body material: carbon steel, cast steel

Applicable media: water, natural gas, oil

Transmission mode: hand wheel, electric, pneumatic

Gate valve standard: JB/T5198-1991

Inspection and test: JB/T9092-1999

Pressure test: GB/T13927-1992

Flange standard: JB/T79.1-79.2 -1994

Product overview

The electric flat gate valve with guide hole is widely used in natural gas, petroleum, chemical industry, environmental protection, urban pipeline, gas pipeline and other transmission pipelines, vent system and steam storage device as opening and closing equipment. It is especially suitable for long-distance pipelines for natural gas exploitation and purification. The sulfur resistant series products are suitable for long-distance natural gas transmission pipelines with hydrogen sulfide containing medium, fast flow rate, many impurities and serious corrosion.

Structural features

1. The valve body has two structures: casting and welding. Among them, the short plate gate valve without diversion hole adopts the welding structure, the structure length is short, and the weight is light, which is especially suitable for devices that require light weight.

2. The structure of the floating valve seat makes the inlet and outlet of the valve can be sealed in both directions.

3. The valve seat is sealed with double seals, which has the function of double sealing. PTFE can remove sand particles and dirt by itself to ensure a good seal.

4. Valves with hard sealing structure, the sealing surface is welded with Co-based hard alloy, and the hardness reaches HRC44-52 to ensure the reliability of the seal.

5. For the valve with diversion hole structure, regardless of the fully open or fully closed state, the gate and the valve seat are always in contact with each other, and the sealing surface is not directly washed by the medium, thereby prolonging the service life.

6. The fire-resistant design of the valve complies with the standards of API 6FA and API 607, corresponding to the valves used in hydrocarbon flow liquids and oil and gas pipelines. The implementation of this standard can meet the fire protection requirements.

7. When the valve is fully opened, the channel is a straight pipeline, and the flow resistance coefficient and pressure loss are small, and the pipeline can be cleaned by a hair ball.

8. The valve is equipped with an automatic pressure relief protection device to ensure safe use.

9. Fully enclosed structure, good protection performance, can be used all day.

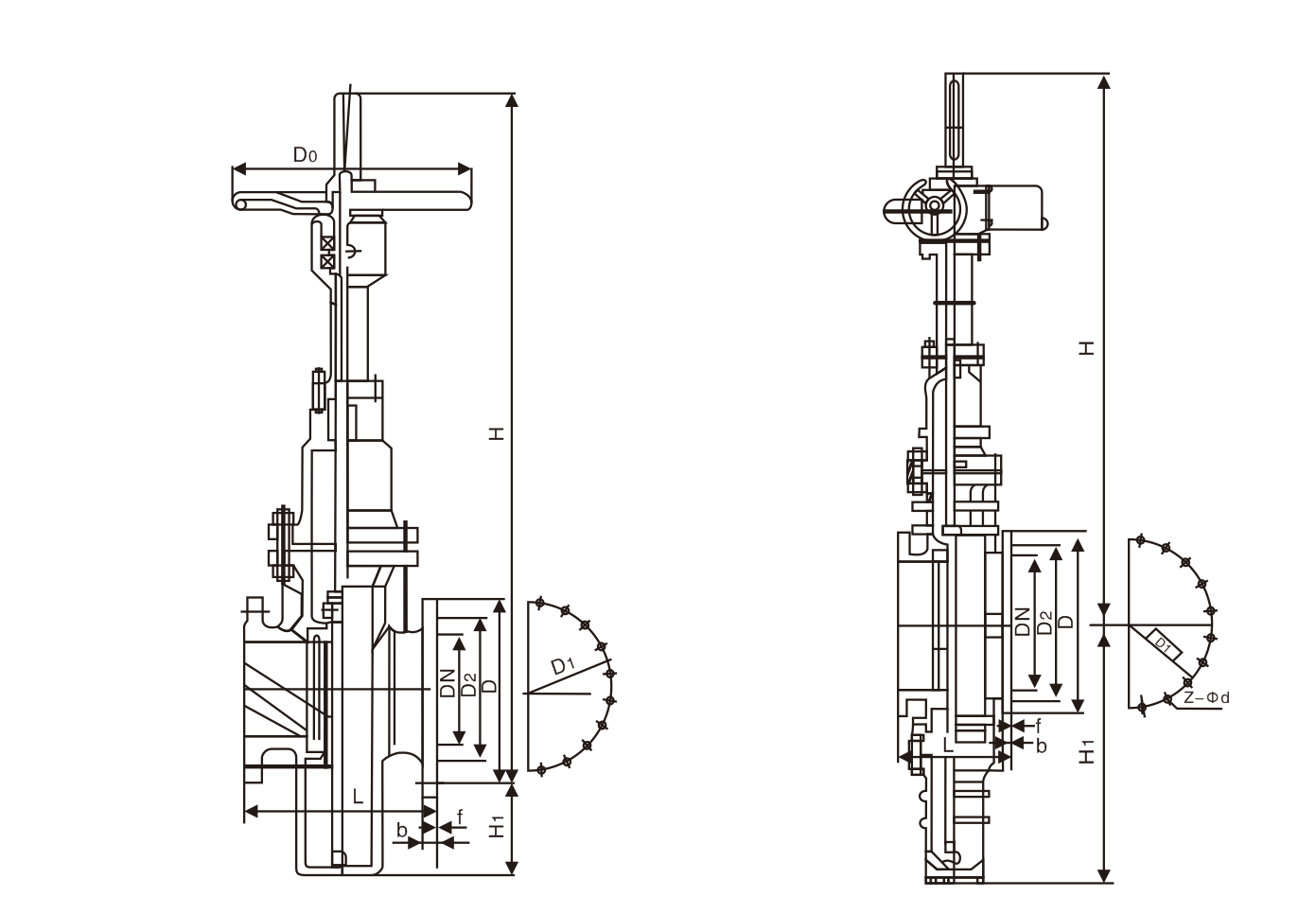

Main external connection size

| Nominal pressure(PN) | DN (mm) | L | D | D1 | D2 | D0 | f | b | H | H1 | Z-φd |

| DPZ943F | |||||||||||

| 1.6MPa | 50 | 178 | 165 | 125 | 102 | 250 | 2 | 18 | 584 | 80 | 4-18 |

| 65 | 190 | 185 | 145 | 122 | 250 | 2 | 18 | 634 | 95 | 8-18 | |

| 80 | 203 | 200 | 160 | 138 | 250 | 2 | 20 | 688 | 100 | 8-18 | |

| 100 | 229 | 220 | 180 | 158 | 300 | 2 | 20 | 863 | 114 | 8-18 | |

| 125 | 254 | 250 | 210 | 188 | 350 | 2 | 22 | 940 | 132 | 8-18 | |

| 150 | 267 | 285 | 240 | 212 | 350 | 2 | 22 | 1030 | 150 | 8-22 | |

| 200 | 292 | 340 | 295 | 268 | 350 | 2 | 24 | 1277 | 168 | 12-22 | |

| 250 | 330 | 405 | 355 | 320 | 400 | 2 | 26 | 1491 | 203 | 12-26 | |

| 300 | 356 | 460 | 410 | 378 | 450 | 2 | 28 | 1701 | 237 | 12-26 | |

| 350 | 381 | 520 | 470 | 428 | 500 | 2 | 30 | 1875 | 265 | 16-26 | |

| 400 | 406 | 580 | 525 | 490 | 305 | 2 | 32 | 2180 | 300 | 16-30 | |

| 450 | 432 | 640 | 585 | 550 | 305 | 2 | 40 | 2440 | 325 | 20-30 | |

| 500 | 457 | 715 | 650 | 610 | 305 | 2 | 44 | 2860 | 360 | 20-33 | |

| 600 | 508 | 840 | 770 | 725 | 305 | 2 | 54 | 3450 | 425 | 20-36 | |

| 700 | 610 | 910 | 840 | 795 | 305 | 2 | 42 | 3960 | 460 | 24-36 | |

| 800 | 660 | 1025 | 950 | 900 | 305 | 2 | 42 | 4550 | 512 | 24-39 | |

| 900 | 711 | 1125 | 1050 | 1000 | 250 | 2 | 44 | 5250 | 565 | 28-39 | |

| 1000 | 811 | 1255 | 1170 | 1115 | 250 | 2 | 46 | 5870 | 630 | 28-42 | |

| 2.5MPa | 50 | 178 | 165 | 125 | 102 | 250 | 2 | 20 | 584 | 80 | 4-18 |

| 65 | 190 | 185 | 145 | 122 | 300 | 2 | 22 | 634 | 95 | 8-18 | |

| 80 | 203 | 200 | 160 | 138 | 350 | 2 | 24 | 688 | 100 | 8-18 | |

| 100 | 229 | 235 | 190 | 162 | 350 | 2 | 24 | 863 | 114 | 8-22 | |

| 125 | 254 | 270 | 220 | 188 | 350 | 2 | 26 | 940 | 132 | 8-26 | |

| 150 | 267 | 300 | 250 | 218 | 400 | 2 | 28 | 1030 | 150 | 8-26 | |

| 200 | 292 | 360 | 310 | 278 | 450 | 2 | 30 | 1277 | 168 | 12-26 | |

| 250 | 330 | 425 | 370 | 335 | 500 | 2 | 32 | 1491 | 203 | 12-30 | |

| 300 | 356 | 485 | 430 | 395 | 305 | 2 | 34 | 1701 | 237 | 16-30 | |

| 350 | 381 | 555 | 490 | 450 | 305 | 2 | 38 | 1875 | 265 | 16-33 | |

| 400 | 406 | 620 | 550 | 505 | 305 | 2 | 40 | 2180 | 300 | 16-36 | |

| 450 | 432 | 670 | 600 | 555 | 305 | 2 | 46 | 2440 | 325 | 20-36 | |

| 500 | 457 | 730 | 660 | 615 | 305 | 2 | 48 | 2860 | 360 | 20-36 | |

| 600 | 508 | 845 | 770 | 720 | 305 | 2 | 58 | 3450 | 425 | 20-39 | |

| 700 | 610 | 960 | 875 | 820 | 305 | 2 | 50 | 3960 | 460 | 24-42 | |

| 800 | 660 | 1085 | 990 | 930 | 305 | 2 | 54 | 4550 | 512 | 24-48 | |

Jing12011202000600

Jing12011202000600