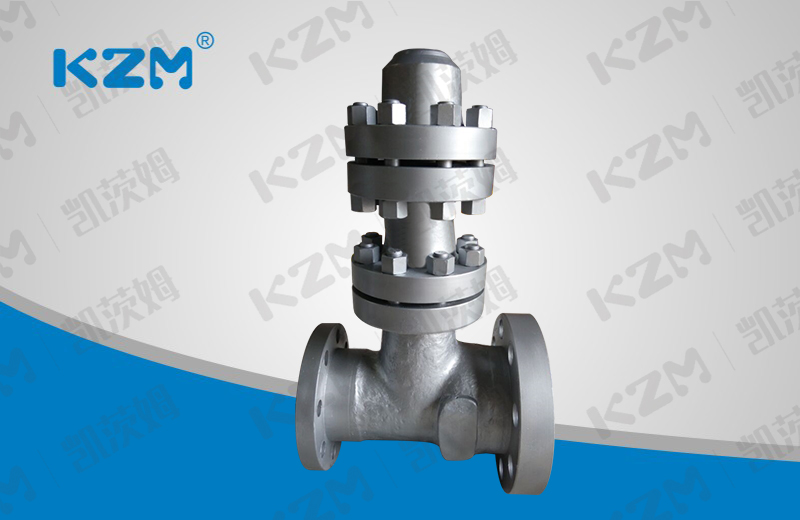

Empty check valve

Product overview

Nominal diameter: DN100~250mm

Nominal pressure: PN20MPa

Working temperature: ≤160℃

Design and manufacturing: ASME B16.34, JB/T3595, E101

Pressure temperature: ANSI B16.34, JB/T74, JB/T3595, E101

Structure length: ANSI B16.10, E101, GB/T15188.1, JB/T2766

Butt welding connection size: ASME B16.25, GB/T12224, E101

Inspection and test: ISO5208, GB/T13927, JB/T3595

Product description

The emptying check valve is installed on the outlet pipe of the high-pressure feed pump of the thermal power unit to prevent the feed water from flowing back and protect the feed water pump. This valve works with the automatic recirculation bypass valve of the small flow of the water pump. When the feed water pump is under low load or the outlet shut-off door is closed, the automatic recirculation bypass valve should be in the open position to ensure the safe operation of the water pump. When the dry exhaust check valve is opened, the recirculation bypass valve is automatically closed. It is not suitable for medium containing solid particles and high viscosity.

Working principle

Open the outlet valve and start the feedwater pump. After the feedwater reaches a certain pressure, the valve flap rises to a certain height under the action of the feedwater pressure, pushes away from the valve seat, and the feedwater flows out. At the same time, as the valve flap rises, the connecting rod is driven to rotate, and the valve plate of the emptying port is toggled, so that the recirculating blade-type valve moves downwards and closes the emptying port. When the feed water flow rate decreases, the valve flap falls, pushing the connecting rod to open the emptying valve plate, and opening the recirculation door to maintain a small allowable flow rate of the water pump. When the pump is stopped, the valve flap automatically drops to close the valve port passage to prevent damage to the water supply system by high-pressure water hammer. This valve works with the recirculation bypass valve to maintain the safe operation of the system. The main valve flap moves up and down. When the medium flows back, the channel is closed by the pressure of the medium and the spring. At this time, the bypass valve opens. When the main valve flap is fully opened, the bypass valve closes. The disc seal is made of stainless steel surfacing welding, which has strong wear resistance, scratch resistance and reliable sealing. ·The valve should be installed vertically.

Features

1. The valve works with the recirculation bypass valve to maintain the safe operation of the system.

2. The main valve flap moves up and down. When the medium flows back, the channel is closed with the help of medium pressure and spring. At this time, the bypass valve opens. When the main valve flap is fully opened, the bypass valve closes.

3. The valve disc seal is made of stainless steel surfacing welding, which is wear-resistant, scratch-resistant, and has a reliable seal.

4. The valve should be installed vertically.

Main material

Part Name | Material |

Body, connecting flange, exhaust flange, flange cover | Carbon cast steel |

Guide shaft, fork, shaft sleeve, slider, exhaust sleeve, exhaust plate | Stainless steel |

Disc, disc body, disc shaft, connecting fork | High quality carbon steel |

Bushing | Cast aluminum bronze |

Bolts and nuts | High quality carbon steel |

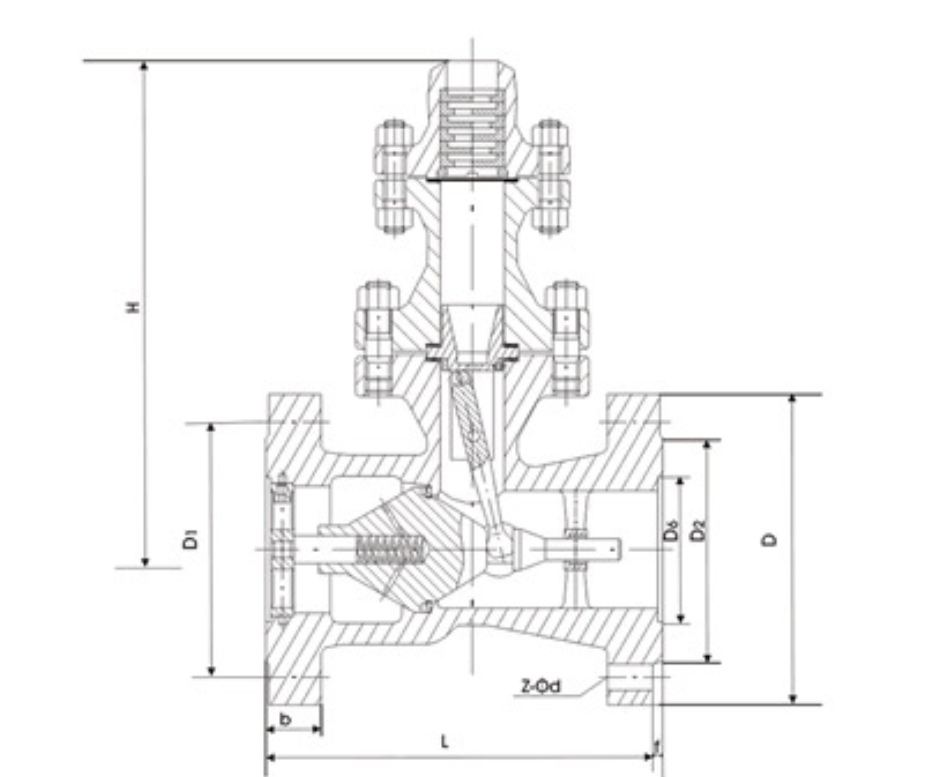

Main external connection size

DN | L | D | D1 | D2 | D6 | b | Z-d | f | f2 | H | weight(kg) |

100 | 430 | 360 | 292 | 245 | 138 | 66 | 8-Ф41 | 3 | 6 | 630 | 285 |

150 | 550 | 440 | 360 | 305 | 190 | 82 | 12-Ф48 | 3 | 6 | 650 | 510 |

175 | 610 | 475 | 3944 | 340 | 214 | 84 | 12-Ф48 | 3 | 6 | 685 | 700 |

225 | 900 | 580 | 483 | 418 | 268 | 100 | 12-Ф58 | 3 | 6 | 765 | 1105 |

250 | 900 | 670 | 572 | 508 | 319 | 110 | 16-Ф58 | 3 | 6 | 780 | 1330 |

Jing12011202000600

Jing12011202000600