Product description

The air extraction check valve is installed in the horizontal steam extraction pipeline leading from the low pressure steam guide pipe in the steam turbine, mainly to prevent the steam in the extraction steam pipeline, or backflow in the event of an accident, causing the turbine to overspeed. It protects important facilities such as steam turbine pumps, and its performance requirements are that the valve closes instantaneously and the closing time is less than 0.5 seconds under abnormal conditions such as pipeline media backflow, power failure, and accidents.

Features

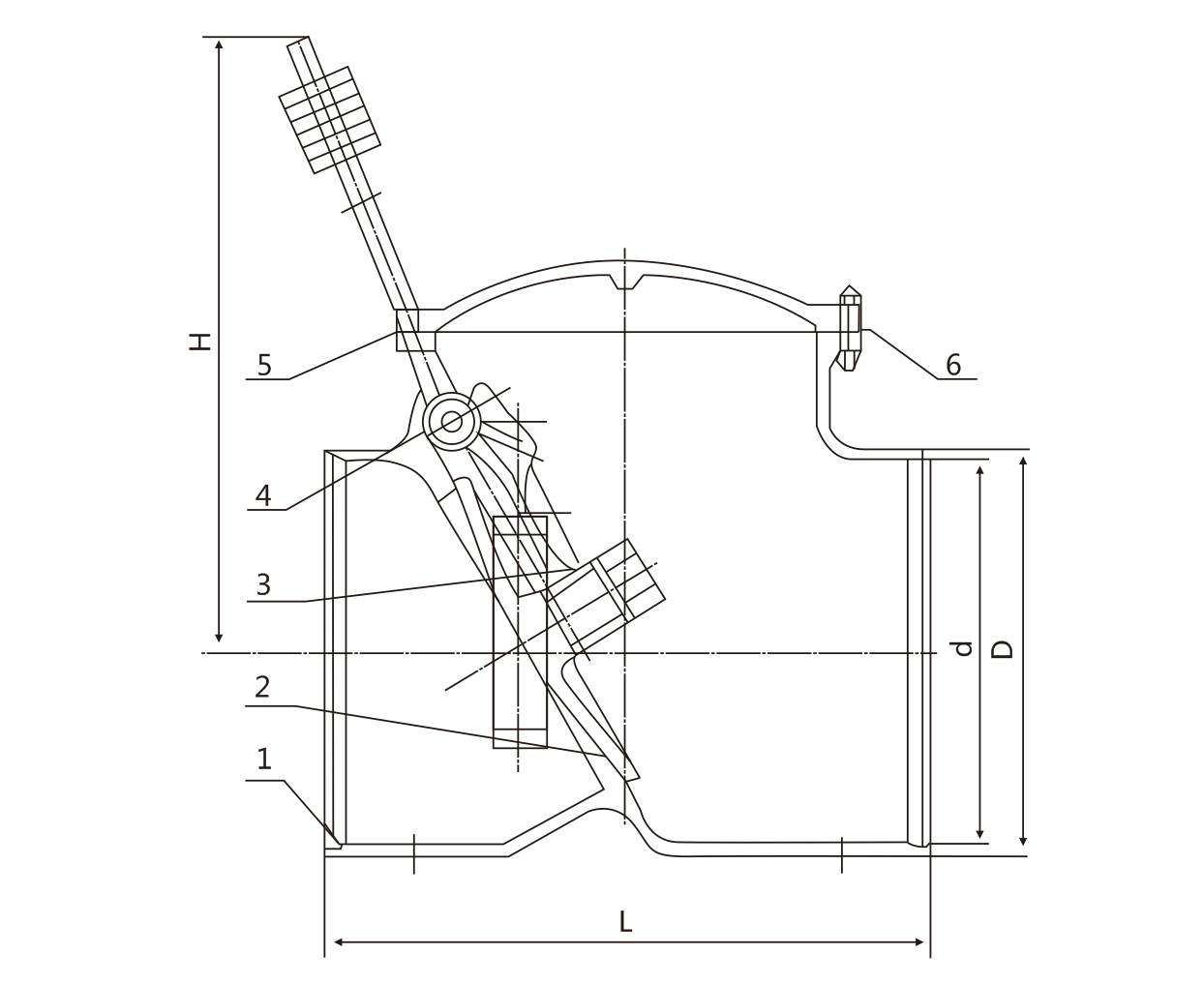

1. Free swinging valve clack; the valve clack is in the body cavity to connect the pin shaft, and can swing freely under the action of the medium.

2. Automatically adjust the valve flap and valve flap arm; the installation position of the valve flap and valve flap arm can be adjusted freely.

3. The design of the inclined valve seat; the sealing surface of the valve seat is inclined at an angle, which is more convenient for the automatic reset of the valve disc, and the sealing is reliable.

4. Balance shaft structure: A balance shaft is added to the outside to make the medium flow smoothly and reduce disc jitter and noise.

5. Streamlined valve body design; the inner cavity of the valve body is designed with a linear flow structure, which makes the medium flow smoothly and does not produce eddy currents.

6. Outer lever; a transmission lever is set on the outer side to facilitate the transmission of torque.

7. Power cylinder operation. The drive cylinder is added to ensure that the valve closes quickly and prevent the medium from flowing back.

Main performance parameters

model | PN | Working pressure/Mpa | Applicable temperature/℃ | Applicable medium |

H664H-20 | 20 | 2.0 | ≤427 | steam |

H664H-50 | 50 | 5.0 | ||

H664H-100 | 100 | 10.0 | ||

H664Y-100I | 100 | 10.0 | ≤540 |

Material of main parts

1 | Body | WCB | 12 | End cap | WCB |

2 | Disc | 25/1Cr18NiTi | 13 | Valve shaft | 1Cr18NiTi |

3 | Stem | 2Cr13/1Cr18NiTi | 14 | Manual test operation valve | 1Cr18NiTi |

4 | Guide sleeve | 2Cr13/1Cr18NiTi | 15 | Intake pipe | Copper tube |

5 | Packing | Flexible graphite | 16 | 2-position 5-port solenoid valve | Assembly |

6 | Packing gland | 25 | 17 | Close valve trachea | Copper tube |

7 | Bracket | WCB | 18 | Open valve trachea | Copper tube |

8 | Indicator plate | 25 | 19 | Quick exhaust valve | Assembly |

9 | Stem | 2Cr13/1Cr18NiTi | 20 | Quick exhaust valve | Assembly |

10 | Help off the cylinder | Assembly | 21 | Signal feedback device | Assembly |

11 | Air source treatment triple | Standard Parts | 22 | Signal feedback device | Assembly |

Main external connection size

PN20 | |||||||||||||||||||

NPS ( in ) | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | 28 | 30 | 36 | |||||||

DN ( mm ) | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 700 | 750 | 900 | |||||||

L | 320 | 450 | 540 | 610 | 650 | 650 | 740 | 790 | 915 | 1040 | 1120 | 1450 | |||||||

H | 258 | 300 | 355 | 425 | 438 | 480 | 535 | 555 | 615 | 782 | 825 | 930 | |||||||

d | 152 | 201 | 252 | 288 | 328 | 376 | 425 | 472 | 568 | 670 | 715 | 880 | |||||||

D | 182 | 235 | 295 | 350 | 380 | 435 | 486 | 540 | 645 | 740 | 800 | 650 | |||||||

Wt ( Kg ) | 85 | 144 | 225 | 350 | 372 | 495 | 625 | 770 | 1305 | 1870 | 1990 | 2350 | |||||||

PN25 | |||||||||||||||||||

NPS ( in ) | 6 | 8 | 10 | 12 | 14 | 20 | 24 | ||||||||||||

DN ( mm ) | 150 | 200 | 250 | 300 | 350 | 500 | 600 | ||||||||||||

L | 420 | 526 | 580 | 610 | 700 | 800 | 850 | ||||||||||||

H | 305 | 348 | 410 | 448 | 475 | 620 | 702 | ||||||||||||

d | 152 | 201 | 252 | 288 | 318 | 458 | 545 | ||||||||||||

D | 182 | 235 | 295 | 350 | 386 | 530 | 640 | ||||||||||||

Wt ( Kg ) | 126 | 210 | 325 | 480 | 575 | 1145 | 1830 | ||||||||||||

PN100 | |||||||||||||||||||

NPS ( in ) | 6 | 8 | 10 | 12 | 14 | 20 | 24 | ||||||||||||

DN ( mm ) | 150 | 200 | 250 | 300 | 350 | 500 | 600 | ||||||||||||

L | 420 | 526 | 580 | 610 | 650 | 680 | 960 | ||||||||||||

H | 365 | 432 | 498 | 578 | 660 | 805 | 900 | ||||||||||||

d | 138 | 182 | 224 | 300 | 352 | 446 | 532 | ||||||||||||

D | 196 | 250 | 298 | 386 | 430 | 536 | 645 | ||||||||||||

Wt ( Kg ) | 215 | 400 | 600 | 1060 | 1435 | 2455 | 3620 | ||||||||||||

Jing12011202000600

Jing12011202000600