Power station swing check valve

Product overview

Product model: H64H/W/Y

Nominal diameter: NPS2"~36"

Nominal pressure: Class150~2500LB

Applicable medium: water, oil, steam, etc.

Design and manufacture: ASME B16.34 E101

Structure length: ASME B16.10 E101

Pressure temperature: ASME B16.34 E101

Test inspection: API598 E101

Product description

Both ends of the branch pipe of the power station swing check valve are welded structure, and the welded groove can be made according to the standard or user requirements. It has the advantages of wear resistance, high temperature resistance, corrosion resistance, abrasion resistance and long service life. It is suitable for high temperature and high pressure water, steam, oil, and superheated steam pipelines in thermal power plants, petrochemicals, metallurgy, etc. with a working pressure of 1500~2500 and a working temperature of -29~570℃. It is used as a device to prevent medium backflow.

Features

1. The product is designed and manufactured in accordance with ANSI B16.34 and E101 standards, and can be equipped with imported equipment.

2. Adopt pressure self-sealing sealing structure, reliable sealing, suitable for ultra-high pressure and high temperature working conditions.

3. The sealing surface of the valve disc and valve seat is made of stellite cobalt-based hard alloy surfacing welding, which is wear-resistant, high temperature resistant, good scratch resistance and long service life.

4. The swing valve clack closes itself by its own weight and medium force.

5. The valve flap rotates around the pin shaft outside the valve seat to reduce the violent impact when it is closed.

6. Built-in pin shaft structure reduces external leakage points and is more reliable in use.

Material of main parts

| Part Name | Material designation | |||

| Body | WCB | WC1 | WC6 | WC9 |

| Seat | A105 | 15CrMoA | 12Cr1MoVA | |

| Disc | WCB | WC1 | WC6 | WC9 |

| Joystick | WCB | WC1 | WC6 | WC9 |

| Cap | A105 | 15CrMoA | 12Cr1MoVA | |

| Seal ring | 1Cr17Ni2 | 12Cr1MoVA | ||

| Seal ring | S mild steel (reinforced flexible graphite) | S mild steel | F mild steel | |

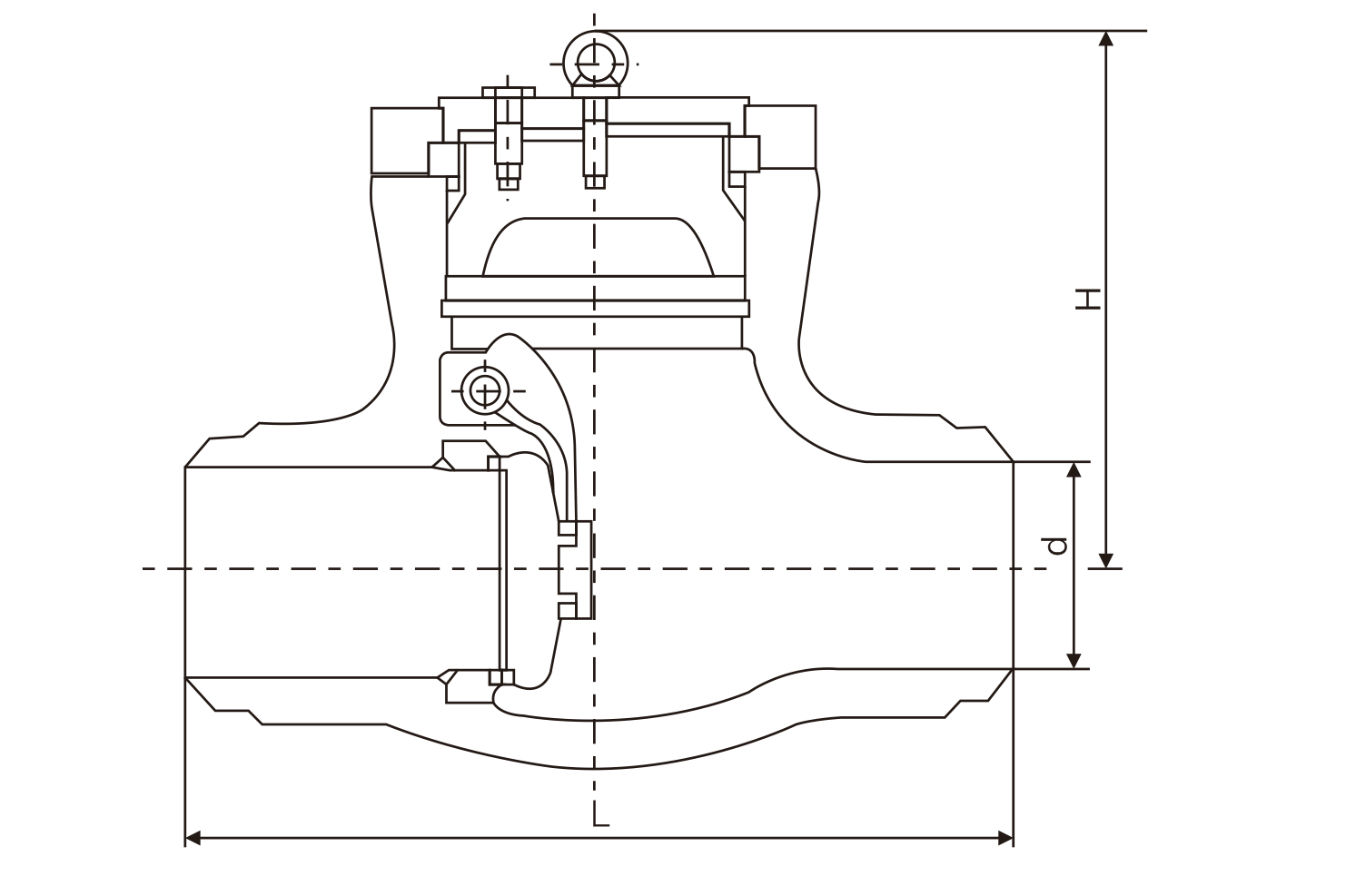

Main external connection size(H64Y-1500Lb H64Y-250/P55140V)

| NPS(in) | d | L | H | WT(kg) |

| 2-1/2 | 62 | 419 | 282 | 57 |

| 3 | 74 | 470 | 300 | 57 |

| 4 | 100 | 546 | 350 | 80 |

| 5 | 144 | 673 | 425 | 115 |

| 6 | 144 | 705 | 400 | 180 |

| 8 | 292 | 832 | 490 | 270 |

| 10 | 239 | 991 | 540 | 430 |

| 12 | 287 | 113 | 650 | 630 |

| 14 | 315 | 1257 | 710 | 1400 |

Main external connection size(H64Y-2000Lb H64Y-320/P55170V)

| NPS(in) | d | L | H | WT(kg) |

| 2-1/2 | 50 | 330 | 240 | 40 |

| 3 | 60 | 368 | 305 | 60 |

| 4 | 80 | 457 | 315 | 95 |

| 5 | 96 | 533 | 409 | 170 |

| 6 | 118 | 610 | 465 | 186 |

| 8 | 147 | 762 | 528 | 415 |

| 10 | 180 | 914 | 613 | 658 |

| 12 | 222 | 1041 | 680 | 1200 |

| 14 | 254 | 1118 | 745 | 1638 |

Main external connection size(H64Y-2500Lb H64Y-420/P55250V)

| NPS(in) | d | L | H | WT(kg) |

| 3 | 62 | 578 | 297 | 44 |

| 4 | 81 | 673 | 385 | 110 |

| 5 | 86 | 794 | 410 | 130 |

| 6 | 131 | 914 | 455 | 192 |

| 8 | 179 | 1022 | 557 | 466 |

| 10 | 223 | 1270 | 615 | 730 |

| 12 | 265 | 1422 | 715 | 1120 |

| 14 | 292 | 1118 | 790 | 1495 |

| 16 | 333 | 1245 | 815 | 1950 |

| 18 | 374 | 1397 | 815 | 2400 |

Jing12011202000600

Jing12011202000600