Electric water seal gate valve

Product overview

Product model: DSZ964H

Nominal diameter: DN50~4600mm

Nominal pressure: PN1.0~10.0MPa

Main material: carbon steel, alloy steel

Applicable temperature: ≤540℃ or ≤425℃

Applicable medium: water, steam, oil, non-corrosive gas

Design standard: GB/T12234

Structure length: GB/T12221

Connection standard: JB79, GB/T9113

Pressure test: JB/T9092, GB/T13927

Product description

Electric water-sealed gate valve is suitable for opening and closing devices on pipelines with nominal pressure ≤100MPa, working temperature ≤425°C, and working medium of water, steam, oil and non-corrosive gas. The electric water seal gate valve is especially suitable for the vacuum condensing system of the steam turbine of the thermal power plant.

Features

1. The valve cover packing chamber of this product has a water-tight structure. When water with a pressure of 0.6 to 1.0 MPa is introduced into the interface, the system can be isolated from the atmosphere and ensure that the system has a good air seal.

2. The DS/Z series adopts double gate two-way elastic sealing, which is flexible, fast and reliable in opening and closing.

3. The product structure is simple, compact and reasonable, convenient for maintenance and long service life.

4. Used as an opening and closing device on the pipeline, it must be in a fully open or fully closed state, and must not be used to adjust the flow.

5. There are two types of valve connection methods: flange and welding, and the driving method is electric.

Main performance specifications

| Performance test | Nominal pressure (MPa) | |||||

| Shell strength test | 1.0 | 1.6 | 2.5 | 4.0 | 6.4 | 10.0 |

| Sealing test | 1.5 | 2.4 | 3.8 | 6.0 | 9.6 | 15.0 |

| Upper seal test | 1.1 | 1.8 | 2.8 | 4.4 | 7.0 | 11.0 |

| Hermetic test | 1.1 | 1.8 | 2.8 | 4.4 | 7.0 | 11.0 |

| Product Type | Applicable temperature (℃) | Applicable medium | ||||

| Carbon steel type | ≤425 | Water, steam, oil, non-corrosive gas | ||||

| Alloy type | ≤540 | |||||

Material of main parts

| 1 | Body | WCB、ZG1Cr5Mo、ZG1Cr18Ni9Ti、ZG1Cr18Ni12Mo2Ti |

| 2 | Gate | WCB、1Cr18Ni9Ti、1Cr18Ni12Mo2Ti |

| 3 | Gasket | PTFE, metal graphite spiral wound gasket |

| 4 | Cap | WCB/25、ZG1Cr5Mo、ZG1Cr18Ni9Ti、ZG1Cr18Ni12Mo2Ti |

| 5 | Packing | Teflon, flexible graphite, oil-impregnated asbestos packing |

| 6 | Packing gland | 25、2Cr13、1Cr18Ni9Ti、1Cr18Ni12Mo2Ti |

| 7 | Stem | 2Cr13、1Cr18Ni9Ti、1Cr18Ni12Mo2Ti |

| 8 | Bracket | HT200、WCB、1Cr18Ni9Ti |

| 9 | Electric Actuator | Housing(HT200、WCB) |

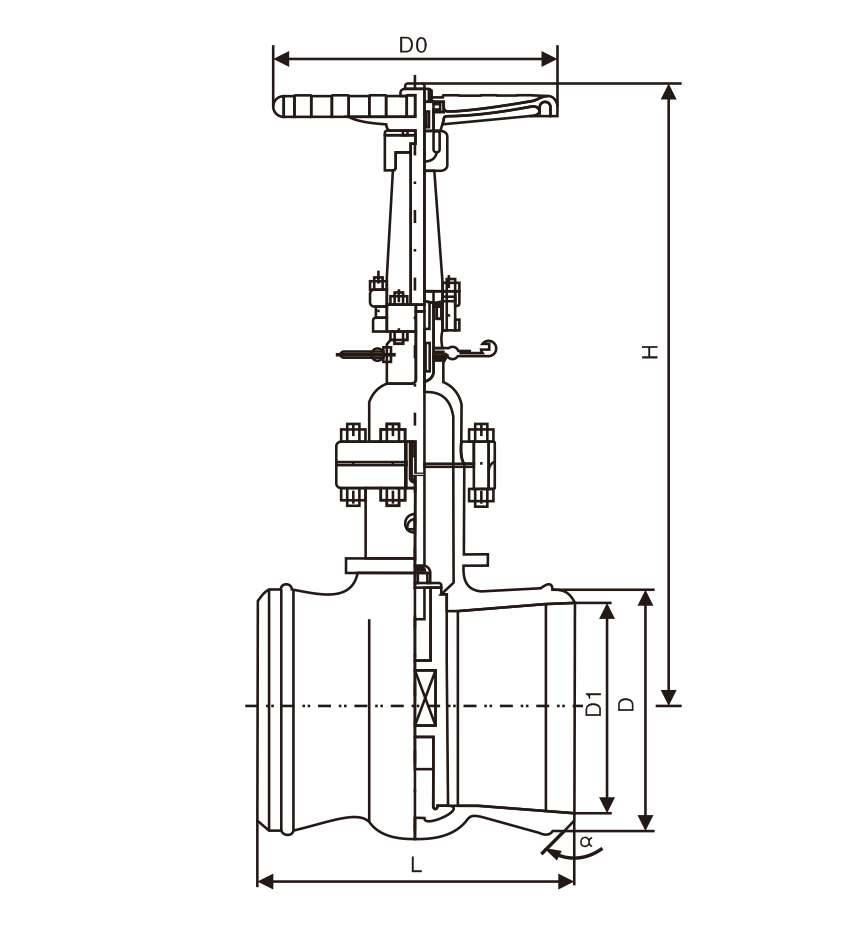

Main external connection size

Nominal diameter DN / mm | L | α | H | D0 | PN1.6MPa | PN2.5MPa | ||||

| D | D1 | Denso | D | D1 | Denso | |||||

| 50 | 250 | 37°30' | 334 | 250 | 58 | 50 | DZW10 | 64 | 49 | DZW10 |

| 65 | 270 | 37°30' | 439 | 250 | 75 | 65 | DZW10 | 82 | 67 | DZW10 |

| 80 | 280 | 37°30' | 495 | 300 | 91 | 79 | DZW10 | 95 | 77 | DZW10 |

| 100 | 300 | 37°30' | 575 | 350 | 110 | 97 | DZW15 | 117 | 101 | DZW15 |

| 125 | 325 | 37°30' | 587 | 350 | 136 | 121 | DZW15 | 144 | 126 | DZW20I |

| 150 | 350 | 37°30' | 607 | 350 | 163 | 146 | DZW20I | 172 | 158 | DZW20I |

| 200 | 400 | 37°30' | 740 | 400 | 223 | 202 | DZW20 | 223 | 202 | DZW30 |

| 250 | 450 | 37°30' | 863 | 400 | 278 | 254 | DZW30 | 278 | 254 | DZW30 |

| 300 | 500 | 37°30' | 990 | 400 | 330 | 305 | DZW45 | 330 | 305 | DZW45 |

| 350 | 550 | 37°30' | 1137 | 500 | 382 | 352 | DZW60 | 382 | 352 | DZW60 |

| 400 | 600 | 37°30' | 1523 | 500 | 432 | 399 | DZW60 | 432 | 39g | DZW60 |

| 450 | 650 | 37°30' | 1618 | 600 | 485 | 451 | DZW90 | 485 | 451 | DZW90 |

| 500 | 700 | 37°30' | 1657 | 600 | 535 | 501 | DZW120 | 535 | 499 | DZW120 |

| 600 | 800 | 37°30' | 1746 | 700 | 636 | 601 | DZW180 | 636 | 599 | DZW180 |

Note: PN1.6 (16) valve is allowed to be used as PN1.0 (10) pressure selection.

Main external connection size

Nominal diameter DN / mm | L | D | α | PN4.0MPa | PN6.4MPa | PN10.0MPa | |||||||||

| D1 | H | D0 | Denso | D1 | H | D0 | Denso | D1 | H | D0 | Denso | ||||

| 50 | 250 | 64 | 37°30' | 49 | 345 | 300 | DZW10 | 50 | 350 | 300 | DZW10 | 49 | 350 | 300 | DZW10 |

| 65 | 270 | 83 | 37°30' | 67 | 441 | 300 | DZW10 | 66 | 447 | 300 | DZW15 | 64 | 447 | 300 | DZW15 |

| 80 | 280 | 96 | 37°30' | 79 | 495 | 350 | DZW15 | 77 | 499 | 350 | DZW20I | 75 | 499 | 350 | DZW20I |

| 100 | 300 | 117 | 37°30' | 101 | 575 | 350 | DZW20I | 99 | 582 | 400 | DZW20I | 87 | 582 | 400 | DZW30I |

| 125 | 325 | 144 | 37°30' | 126 | 587 | 400 | DZW20I | 129 | 590 | 400 | DZW30 | 125 | 590 | 400 | DZW30 |

| 150 | 350 | 172 | 37°30' | 152 | 607 | 400 | DZW30 | 150 | 611 | 450 | DZW30 | 145 | 611 | 450 | DZW45 |

| 200 | 400 | 223 | 37°30' | 200 | 740 | 450 | DZW30 | 198 | 745 | 550 | DZW45 | 190 | 747 | 550 | DZW60 |

| 250 | 450 | 278 | 37°30' | 252 | 863 | 550 | DZW45 | 246 | 867 | 650 | DZW60 | 236 | 869 | 650 | DZW90I |

| 300 | 500 | 330 | 37°30' | 302 | 1008 | 650 | DZW60 | 294 | 1008 | 750 | DZW90I | 282 | 1013 | 750 | DZW120I |

| 350 | 550 | 382 | 37°30' | 350 | 1142 | 750 | DZW90I | 342 | 1148 | 800 | DZW120I | 334 | 1148 | 850 | DZW180 |

| 400 | 650 | 432 | 37°30' | 397 | 1527 | 850 | DZW120 | 387 | 1531 | 900 | DZW180 | 377 | 1533 | 950 | DZW250 |

Jing12011202000600

Jing12011202000600